Grounding Systems: TN, TT, and IT Schemes and Applications

Grounding is one of the most crucial technical measures for ensuring electrical safety in power installations.

The purpose of grounding is to connect non-live metal parts of electrical equipment to grounding devices, preventing electric shock hazards for humans and animals.

In three-phase AC networks up to 1 kV, different grounding systems are used based on the neutral configuration and the handling of protective (PE) and neutral (N) conductors.

- TN Systems - Feature a solidly grounded transformer neutral.

- TT System - Uses a locally installed ground electrode for protective grounding.

- IT System - Has an isolated or resistance-grounded neutral to limit fault currents.

TN Grounding System: Types and Configurations

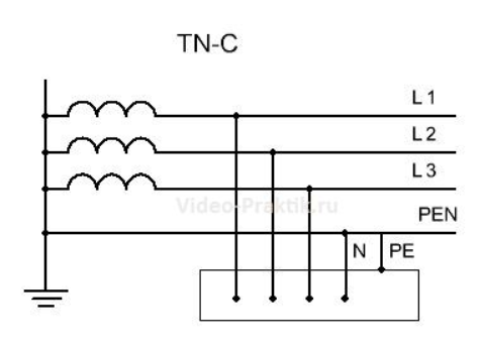

1. TN-C System

The TN-C (Terra Neutral Combined) system has a solidly grounded transformer neutral at the substation.

- Power is delivered via a four-wire system (three-phase conductors + a combined PEN conductor).

- PEN serves as both the neutral (N) and protective earth (PE) conductor.

- No additional grounding electrodes are required on the consumer’s side.

Identifying a TN-C System in a Home

- Three-phase connections use a four-wire setup.

- Single-phase connections use only two wires.

- Older homes have two-prong outlets with no grounding contacts.

Disadvantages of TN-C

- High risk of electric shock - If the PEN conductor is damaged, appliance casings may become live.

- GFCIs (Ground Fault Circuit Interrupters) do not work properly in this system.

Upgrading from TN-C

- Transition to TN-S requires installing a dedicated PE conductor from the substation.

- A simpler alternative is TN-C-S, which involves splitting PEN into PE and N before the electrical panel.

- Installing a GFCI or a circuit breaker with built-in ground fault protection can enhance safety.

2. TN-C-S System

The TN-C-S (Terra Neutral Combined-Separated) system is a hybrid solution.

- Initially, power is distributed via a TN-C (four-wire) system.

- Just before entering the building, the PEN conductor is split into separate PE (ground) and N (neutral) wires.

- The internal electrical distribution uses five wires (three-phase + N + PE).

Advantages of TN-C-S

- Provides basic ground fault protection.

- Allows the use of GFCIs (RCDs), which can trip when leakage currents are detected.

Disadvantages of TN-C-S

- PEN conductor is vulnerable to damage before the split, which can cause dangerous voltage surges.

- Additional grounding electrodes are required at regular intervals (100-200 meters) to maintain safety.

3. TN-S System

The TN-S (Terra Neutral Separated) system provides the highest level of safety.

- The PE and N conductors are completely separate from the substation to the consumer.

- The system uses a dedicated PE conductor throughout the power line, ensuring reliable grounding.

Benefits of TN-S

✅ Reliable grounding reduces electrical shock risks.

✅ No risk of losing ground protection due to PEN conductor failure.

✅ Better protection against voltage surges and faults.

Challenges of TN-S

- Expensive to implement due to the need for additional wiring.

- Difficult to retrofit in existing TN-C networks.

TT and IT Grounding Systems

1. TT Grounding System

The TT system (Terra-Terra) is used when a dedicated protective ground is required at the consumer’s location.

- The PEN conductor is grounded at the substation, but consumers must install their own ground electrode.

- The local PE conductor is isolated from the supply neutral (N).

When Is TT Grounding Used?

- In metallic buildings where the structure itself poses grounding risks.

- In areas where TN systems are impractical due to soil conditions.

- In older buildings that lack dedicated grounding conductors.

Safety Considerations in TT Systems

GFCIs (RCDs) are mandatory with a trip current of ≤30mA.

The grounding resistance (Rz) must be low enough to ensure proper fault protection:

Rz × I_GFCI ≤ 50V

Where:

- Rz = total ground resistance

- I_GFCI = residual current trip threshold

This formula ensures that touch voltage never exceeds 50V, reducing electrocution risks.

2. IT Grounding System

The IT (Isolated-Terra) system differs significantly from TN and TT systems.

- The transformer neutral is either completely isolated or connected through a high resistance.

- No protective earth (PE) conductor is supplied from the substation.

- Consumers must use a local grounding system for safety.

Where Is IT Grounding Used?

- Industrial plants, chemical plants, and oil refineries where equipment safety is critical.

- Hospitals - IT reduces the risk of ground faults affecting medical equipment.

- Explosive environments - IT grounding limits short-circuit currents, preventing sparks.

Advantages of IT Grounding

✅ Minimal fault currents prevent electrical fires.

✅ Systems can continue operating after the first ground fault.

✅ Ideal for high-risk environments.

Challenges of IT Grounding

- Complex and expensive to install.

- Requires regular insulation resistance monitoring to detect ground faults.

- Not suitable for standard residential buildings.

Comparison Table: TN, TT, and IT Systems

| Feature | TN-C | TN-C-S | TN-S | TT | IT |

|---|---|---|---|---|---|

| Separate N and PE | ❌ | ✅ (after split) | ✅ | ✅ | ✅ |

| Requires local ground? | ❌ | Optional | Optional | ✅ | ✅ |

| Supports GFCIs? | ❌ | ✅ | ✅ | ✅ | ✅ |

| Common in homes? | ✅ (old) | ✅ | ✅ | ❌ | ❌ |

| Industrial use? | ❌ | ✅ | ✅ | ✅ | ✅ |

| Best fault protection | ❌ | ✅ | ✅ | ✅ | ✅ |

| Cost to install | Low | Medium | High | High | Very High |

Conclusion: Choosing the Right Grounding System

- TN-S is the safest system but is costly to implement.

- TN-C-S is a good compromise for improving safety in older TN-C installations.

- TT is useful when a separate ground electrode is necessary.

- IT is ideal for critical infrastructure and industrial settings.

For residential and commercial buildings, TN-C-S or TN-S are the best options for ensuring safety and electrical reliability.

If upgrading from TN-C, consult a licensed electrician to transition to a safer grounding system!