Why Electrical Insulation Matters

Electrical insulation is essential for ensuring the safety and longevity of electrical systems. A high-quality insulation layer prevents electric shocks, short circuits, and fire hazards.

In the United States, improper or deteriorated wiring insulation is one of the leading causes of residential fires. Statistics show that nearly 30% of home fires originate from faulty electrical systems, emphasizing the importance of selecting the right insulation material.

This guide covers the best insulation materials, their properties, and recommendations for electrical installations in homes, businesses, and industrial applications.

Top Electrical Insulation Materials

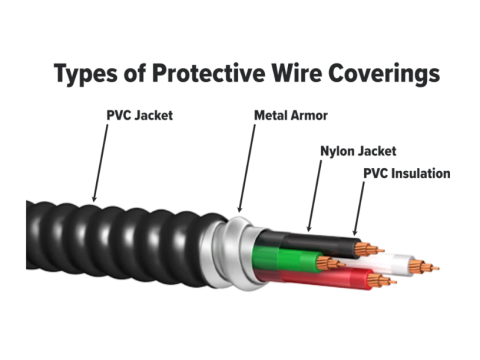

1. Polyvinyl Chloride (PVC) Insulation

PVC insulation is one of the most commonly used materials in electrical wiring. It offers excellent durability, flexibility, and resistance to moisture and chemicals.

Advantages of PVC Insulation:

- Affordable and widely available

- Self-extinguishing properties for fire safety

- Resists moisture and corrosion

- Suitable for indoor and outdoor use

Best Uses:

PVC insulation is ideal for general household wiring, commercial buildings, and light industrial applications.

2. Rubber Insulation

Rubber insulation provides high flexibility and resilience, making it suitable for wiring systems exposed to frequent movement or vibration.

Advantages of Rubber Insulation:

- Excellent elasticity and impact resistance

- High electrical insulation properties

- Suitable for environments with mechanical stress

Best Uses:

Rubber-insulated wires are commonly used in power tools, industrial machinery, and outdoor electrical applications.

3. Polyethylene (PE) and Cross-Linked Polyethylene (XLPE) Insulation

Polyethylene insulation offers high electrical resistance, while XLPE provides enhanced thermal stability and mechanical strength.

Advantages of XLPE Insulation:

- Can withstand temperatures up to 194°F (90°C)

- High resistance to moisture and chemicals

- Longer lifespan than standard polyethylene insulation

Best Uses:

Ideal for high-voltage power cables, underground wiring, and environments exposed to heat and moisture.

Modern Insulation Technologies for Electrical Connections

Heat Shrink Tubing

Heat shrink tubing is a modern insulation technique that provides superior protection against environmental damage.

How It Works:

When exposed to heat, the tubing shrinks to fit tightly around the wire, forming a durable, waterproof seal. Some variants contain adhesive layers for enhanced insulation.

Best Uses:

- Electrical splicing and repairs

- Outdoor wiring protection

- Industrial and automotive applications

Electrical Tape

Electrical tape remains a cost-effective insulation solution, commonly made from PVC or rubber materials.

Best Practices for Using Electrical Tape:

- Wrap multiple layers for extra durability

- Use high-quality, non-conductive tape for safety

- Avoid stretching the tape too tightly, as it may degrade over time

Wire Sleeves and Insulation Tubes

Wire sleeves and insulation tubes provide additional protection against mechanical wear and extreme temperatures.

Popular Sleeve Materials:

- Silicone: High heat resistance

- Fiberglass: Fire-resistant and durable

- Teflon: Excellent chemical resistance

Specialized Electrical Insulation Types

Fire-Resistant Insulation

Fire-resistant cables, such as FRLS (Flame Retardant, Low Smoke) and LSZH (Low Smoke, Zero Halogen), are used in buildings where fire safety is a top priority.

Best Uses:

- Fire alarm systems

- Emergency lighting circuits

- High-rise buildings

Oil-Resistant Insulation

Oil-resistant insulation is necessary for environments where electrical wiring is exposed to lubricants, fuels, and industrial chemicals.

Best Uses:

- Automotive wiring

- Factory machinery

- Heavy-duty power cables

Innovations in Electrical Insulation

Self-Healing Insulation Materials

Advanced insulation materials are being developed to self-repair minor damage, reducing the risk of electrical failures. These materials use microcapsules that release an insulating compound when punctured.

Nanocomposite Insulation

Nanotechnology has led to the development of ultra-thin, highly durable insulation materials with enhanced electrical resistance and fireproofing properties.

How to Choose the Right Electrical Insulation

When selecting insulation for electrical wiring, consider the following factors:

- Operating Voltage: Ensure the insulation is rated for the voltage level in your system.

- Temperature Resistance: Choose insulation that can withstand expected operating temperatures.

- Mechanical Protection: In high-traffic or vibrating environments, opt for durable and flexible insulation.

- Environmental Exposure: For outdoor wiring, select insulation resistant to moisture, UV rays, and chemicals.

Final Thoughts

Selecting the right electrical insulation is critical for maintaining a safe and efficient electrical system.

Whether you’re upgrading residential wiring or working on an industrial project, understanding the properties of different insulation materials will help you make the best choice.

For high-quality electrical insulation materials and wiring solutions, visit safsale.com, where you’ll find a wide range of products designed for durability and safety.

Key Takeaways:

✔ PVC, rubber, and XLPE are the most commonly used insulation materials.

✔ Heat shrink tubing and fire-resistant insulation improve safety in critical applications.

✔ Innovations like self-healing and nanocomposite insulation enhance durability.

✔ Choosing the right insulation depends on voltage, temperature, and environmental conditions.

This adaptation provides an SEO-optimized, American market-friendly version of the original content while ensuring clarity, relevance, and engagement.