Introduction: Wiring Installation Methods and Their Importance in the USA

In the United States, electrical wiring must meet strict safety standards to prevent fires, electric shocks, and other hazards. Understanding open and hidden wiring methods is crucial for anyone installing or upgrading an electrical system. Whether you are a DIY enthusiast or a professional electrician, knowing these techniques-and the common mistakes to avoid-helps you comply with National Electrical Code (NEC) requirements and ensure a safe installation.

At safsale.com, we understand the importance of reliable, code-compliant wiring solutions. Our goal is to help you choose the best approach for your specific project and keep your home or business in the USA secure.

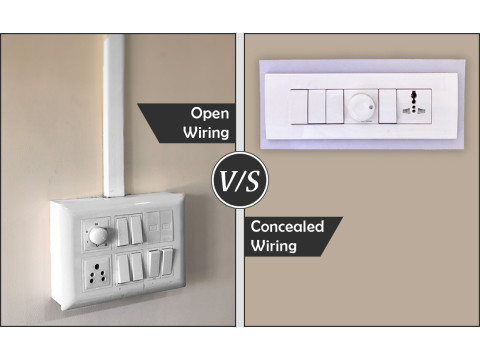

1. Overview of Open Wiring Methods

Open wiring methods involve routing cables and conductors so they remain visible or are placed in easily accessible conduits. This approach is particularly common in certain US residential and light commercial applications, as well as for retrofitting older wooden buildings or log cabins.

Benefits of Open Wiring

- Easy Access for Maintenance: Quick repairs or wire replacements without cutting into walls.

- Lower Installation Cost: Fewer materials and labor hours compared to hidden wiring.

- Visually Appealing for Vintage Designs: In the USA, some homeowners prefer a rustic “retro” look with exposed wiring on porcelain rollers.

Drawbacks of Open Wiring

- Less Fire Protection: Cables are more susceptible to heat and potential damage.

- Higher Risk of Physical Damage: Visible wires can be accidentally cut, knocked loose, or otherwise harmed.

Below are common open wiring techniques recognized in the United States.

1.1 Wiring in Cable Channels

Using plastic or metal cable channels is a popular open-wiring option across the USA. The channels offer partial protection from dust and light mechanical impact. They are especially convenient in log cabins or homes with wood interiors where hidden wiring might be impractical.

- Pros:

- Simplified future upgrades-just open the cable channel to access wires.

- Lower cost compared to hidden wiring.

- Cons:

- Moderately vulnerable to mechanical damage (though better than fully exposed conductors).

- Some homeowners find cable channels less aesthetically pleasing.

Tip: The NEC requires all wiring in wooden structures to be installed with extra precautions to reduce fire risks. Cable channels are often used to comply with these requirements in many American states.

At safsale.com, we carry a wide range of US-approved cable channels designed to protect your wiring while keeping costs down.

1.2 Flexible Conduits and Metal Pipes

Open wiring can also be placed in flexible conduits (like flexible non-metallic tubing) or steel pipes. Conduits offer excellent protection against accidental damage and can be replaced or upgraded with minimal effort.

- Steel Pipes: Provide high-level fire resistance and protect cables from warping or crushing.

- Flexible Conduits: Easy to navigate around corners and tight spaces.

Downside: Installation can be more labor-intensive and material costs may be higher. Nonetheless, many US commercial codes insist on conduit use in certain areas for maximum safety.

1.3 Supporting Wires on Steel Ropes

In exterior applications-especially in rural or industrial settings-cables can be suspended on steel ropes between poles or support structures. This method extends electricity from one building to another or from an external power source to a remote site.

- Advantage: Ideal for bridging long distances (e.g., over fields, driveways).

- Challenges: Must withstand weather, wind load, and potential sagging of cables. Proper tension must be maintained so that mechanical stress doesn’t exceed recommended limits.

2. Hidden (Concealed) Wiring Methods

Hidden (concealed) wiring is the most common approach in modern US homes, especially in urban and suburban areas. The wires are placed behind walls, in ceilings, or under finished surfaces, making them virtually invisible.

Common Concealed Wiring Techniques

- Wires in Wall Grooves (Chases): Carving out channels in concrete, brick, or plaster walls, then routing cables inside before sealing.

- Under Decorative Panels: Running conductors along the wall surface, then covering them with drywall, wood panels, or other decorative materials.

- In Conduits Behind Wall Finishes: Pulling wires through flexible or rigid conduits hidden behind wallboard.

2.1 Wiring in Wall Grooves

Pros:

- Maximum protection from mechanical damage.

- Leaves walls looking “clean” with no visible cables.

Cons:

- Demanding and dusty installation process.

- Requires specialized tools like a rotary hammer, chase cutter, or angle grinder.

- Future access or repairs necessitate cutting through the wall again.

2.2 Wiring Under Decorative Panels

An alternative for spaces where removable wall panels (such as drywall, MDF, or wood planks) are used. The cables are laid flat on the wall surface and hidden behind the finishing material.

- Benefit: Easier to access wires by removing a section of the paneling.

- Drawback: Still some hassle in removing panels, especially if they're painted or finished.

Expert Advice: Consider pulling the wires inside flexible plastic conduits or corrugated tubing. If repairs are necessary, the wiring can be carefully extracted without removing every panel.

3. Common Mistakes in Wiring Installation

Both open and hidden wiring can be installed incorrectly if proper methods aren’t followed. Below are typical errors frequently seen in the USA, especially with DIY or rushed projects.

3.1 Poor Layout and Planning

- Ignoring local building codes or failing to account for load capacity.

- Running wires too close to gas or water lines, which can violate safety regulations like those in the International Residential Code (IRC) and NEC.

3.2 Improper Cutting and Mounting of Cable Channels

- Using incorrect tools-some installers “snap” plastic channels by hand, weakening the material.

- Overstuffing the channel with too many wires, causing overheating and making future troubleshooting difficult.

3.3 Inadequate Fire Safety Measures

- Not using fire-rated conduits or junction boxes in areas with higher fire risk (kitchens, garages, etc.).

- Skipping metal conduit in wooden constructions where local regulations demand them.

3.4 Using Glue Where Future Modifications Are Likely

- Relying on permanent adhesives to secure cable channels.

- If system expansion is needed, removing glued components can damage walls and wiring.

Practical Tips for Safe and Compliant Installations

- Consult the NEC: Always verify that your wiring method meets or exceeds the requirements of the National Electrical Code.

- Select Proper Materials: Steel conduits for high-fire-risk zones, flexible PVC for easier runs, or cable trays for open installations.

- Use Quality Tools: Reduce errors and damage by employing cutters, chase tools, or specialized sheathing strippers.

- Plan for Future Upgrades: If you anticipate expanding or replacing circuits, choose removable or accessible installations, such as cable channels secured with screws instead of glue.

- Hire Professionals When in Doubt: If unsure, consult a licensed electrician to ensure your work complies with local regulations and codes.

Remember, at safsale.com, we provide a variety of US-compliant wiring solutions-from sturdy conduits to high-quality cable channels-to make your project both safe and efficient.

Conclusion: Ensuring Safe, Efficient Wiring in the United States

Choosing the right wiring installation method-open or hidden-depends on your building type, budget, and regulatory requirements in your region of the USA. While open wiring methods are simpler and more accessible, hidden wiring delivers a sleek finish and better mechanical protection. Both approaches demand careful planning, adherence to the NEC, and high-quality products.

When you trust safsale.com, you gain access to top-of-the-line cable channels, conduits, and accessories for any US wiring project. Our range of products allows you to customize your installation for maximum performance, code compliance, and safety.

For more information or to explore our catalog, visit safsale.com and take the next step toward a secure, long-lasting electrical system.

Why Choose SafSale.com for Your Wiring Needs in the USA?

- We offer code-compliant products suitable for open and hidden wiring.

- Our expert staff can guide you on NEC standards and best practices.

- Competitive pricing on all materials, ensuring you get the best value.

- Fast shipping across the USA, so you can complete your project on schedule.

Explore our selection at safsale.com and build a wiring system that meets American safety and quality standards. No matter which method you choose-open or hidden-our products and expertise will help you get the job done right.