Understanding DC Motors: Types, Excitation, and Brushless Technology

DC motors are widely used in various applications, from home appliances to industrial automation and electric vehicles. Unlike AC motors, DC motors operate on direct current, making them ideal for precise speed control and high torque applications.

This guide explores DC motor types, excitation methods, and the advantages of brushless DC motors.

1️⃣ What is a DC Motor?

A DC motor converts electrical energy into mechanical motion using electromagnetic principles. Unlike AC motors, DC motors can provide variable speed control easily, making them ideal for applications that require precise movement and torque control.

🔹 Main Components of a DC Motor

- Stator (Stationary Part): Creates a constant magnetic field

- Rotor (Armature): Rotates to produce mechanical motion

- Brushes & Commutator (in brushed motors): Helps switch current direction

- Windings: Conducts current to generate magnetic fields

- Power Supply: Provides DC voltage

2️⃣ Types of DC Motors

DC motors are classified based on how their magnetic field is generated.

| DC Motor Type | Excitation Method | Applications |

|---|---|---|

| Brushed DC Motor | Uses carbon brushes & commutator | Toys, small appliances, automotive |

| Brushless DC Motor (BLDC) | Uses electronic controller instead of brushes | Electric vehicles, drones, industrial automation |

| Series DC Motor | Field winding in series with armature | Electric trains, cranes, high-torque applications |

| Shunt DC Motor | Field winding in parallel with armature | Fans, blowers, small conveyors |

| Compound DC Motor | Combines series & shunt windings | Elevators, printing machines |

📌 Brushed DC motors are simple and affordable, while brushless DC motors (BLDC) offer better efficiency and lifespan.

3️⃣ Working Principle of a DC Motor

DC motors operate on Lorentz Force Law, which states that a current-carrying conductor in a magnetic field experiences a force.

🔹 Basic Operation:

1️⃣ When DC voltage is applied, current flows through the armature winding.

2️⃣ The magnetic field interacts with the rotor, creating motion.

3️⃣ In brushed motors, a commutator switches current polarity, maintaining continuous rotation.

4️⃣ In brushless motors, an electronic controller handles commutation, eliminating mechanical wear.

4️⃣ DC Motor Excitation Methods

The excitation method defines how the magnetic field is generated in a DC motor.

🔹 1. Separately Excited DC Motor

- Field winding has a separate power source

- Allows independent speed control

📌 Used in electric trains, automation systems

🔹 2. Series DC Motor

- Field winding is connected in series with the armature

- High starting torque but speed varies with load

📌 Used in cranes, elevators, traction motors

🔹 3. Shunt DC Motor

- Field winding is parallel to the armature

- Provides constant speed, even with varying loads

📌 Used in fans, pumps, blowers

🔹 4. Compound DC Motor

- Combination of series & shunt winding

- Balanced performance - good torque & speed regulation

📌 Used in printing presses, rolling mills

✅ Choosing the right DC motor type depends on torque, speed regulation, and load requirements.

5️⃣ Brushless DC Motors (BLDC): The Future of DC Motors

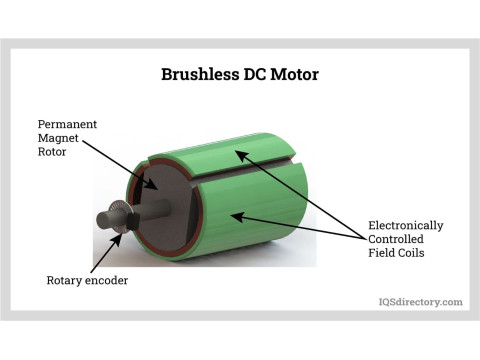

🔹 What is a Brushless DC Motor?

Unlike traditional brushed motors, BLDC motors do not use brushes or a commutator. Instead, they use electronic controllers for switching current in the windings.

🔹 How a BLDC Motor Works

1️⃣ Electronic controller energizes specific windings in a sequence.

2️⃣ The rotor (with permanent magnets) aligns with the stator’s rotating magnetic field.

3️⃣ Sensors (like Hall effect sensors) detect rotor position and adjust switching accordingly.

6️⃣ Why Brushless DC Motors are Better

✔️ Advantages of BLDC Motors

✔ Higher Efficiency - No brush friction losses

✔ Longer Lifespan - No wear and tear of brushes

✔ Better Speed Control - Electronic switching allows precise adjustments

✔ Higher Power Density - More power output in a compact design

✔ Quieter Operation - No electrical noise from commutators

❌ Disadvantages of BLDC Motors

❌ Higher Cost - Requires electronic controller

❌ Complex Circuitry - Needs microcontroller-based operation

📌 BLDC motors are widely used in electric vehicles (EVs), drones, cooling fans, and industrial automation due to their superior efficiency.

7️⃣ Key Differences: Brushed vs Brushless DC Motors

| Feature | Brushed DC Motor | Brushless DC Motor (BLDC) |

|---|---|---|

| Commutation | Uses mechanical brushes | Uses electronic switching |

| Efficiency | Lower due to brush friction | Higher efficiency |

| Lifespan | Shorter due to wear | Longer (no mechanical parts) |

| Maintenance | Requires brush replacement | Low maintenance |

| Noise | Noisy due to brushes | Quiet operation |

| Cost | Cheaper | More expensive |

📌 If you need a low-cost solution, go with brushed DC motors. For durability and high performance, BLDC motors are the best choice!

8️⃣ Applications of DC Motors

📌 Where precise speed control and torque are required:

✔ Electric Vehicles (EVs) - BLDC motors power Tesla, e-bikes, and electric scooters

✔ Industrial Automation - Used in CNC machines, robotics, and actuators

✔ Home Appliances - Fans, refrigerators, washing machines

✔ Drones & RC Vehicles - BLDC motors provide lightweight, high-speed operation

✔ Medical Equipment - Precision movement in surgical and diagnostic devices

✅ The demand for BLDC motors is rapidly increasing in energy-efficient and smart devices!

9️⃣ Choosing the Right DC Motor

📌 Key Considerations:

✔ Torque Requirements - High torque? Series DC motor is best.

✔ Speed Control Needs - Precise speed? Shunt or BLDC motor is ideal.

✔ Efficiency & Longevity - Brushless motors last longer with better efficiency.

✔ Application-Specific Needs - EVs, drones, and automation favor BLDC motors.

🚀 For modern industrial and commercial applications, BLDC motors are the best long-term investment!

🔟 Conclusion: DC Motors for the Future

✅ DC motors are essential for industries requiring precision, speed control, and high torque.

✅ Brushless DC motors (BLDC) are the future of energy-efficient automation.

✅ Understanding excitation types helps in selecting the right motor for your needs.

⚡ Need an efficient motor solution? Upgrade to BLDC motors for maximum performance and longevity!