Interior electrical wiring is the backbone of any home’s power distribution, whether you live in the USA or elsewhere. At safsale.com, we emphasize the importance of careful planning and cable selection to reduce the chances of short circuits, overloads, or other costly failures. This overview explains how indoor wiring is categorized, how it differs in wooden houses, and which cables are best for a trouble-free system.

Throughout the United States, building codes place strict requirements on interior wiring because mistakes here can lead to electric shocks, frequent circuit overloads, or even fires. Paying close attention to cable materials, protective devices, and how lines are run (either open or concealed) helps you avoid such disasters.

Types and Methods of Interior Wiring

When engineers or electricians say “indoor wiring,” they mean all lines operating at up to 1000 V that run inside a home. That includes circuits in walls, floors, and ceilings, plus any open runs along interior surfaces. Typically, you encounter two main categories:

Open Wiring

- The cable is laid along visible surfaces (walls, ceilings, etc.).

- Can be stationary, portable, or mobile, depending on the intended use.

Concealed (Hidden) Wiring

- Wires stay hidden within structural elements or behind finishing materials.

Each approach has pluses and minuses. In the USA, you might see open wiring in older homes or specialized designs, whereas hidden wiring is common in contemporary construction. Here at safsale.com, we field questions every day on which approach suits a particular building or homeowner style.

1. Open Wiring

Open wiring gets affixed directly to walls, ceilings, or indoor structural surfaces. Depending on its purpose, it might be:

- Stationary: permanent lines for main circuits.

- Portable: temporary setups for short-term power needs.

- Mobile: used for devices that frequently change position (some industrial or workshop scenarios).

In a typical American house, open wiring is more frequently done using protective channels or cable raceways rather than leaving bare cables. You see it, for instance, in wooden buildings where local codes might require cables in metal conduits or on standoff insulators for fire safety. Some folks prefer a decorative “retro style” with ceramic supports, especially if they want to preserve a rustic or vintage vibe.

Pros of Open Wiring:

- Installation speed: No chiseling or “chase cutting” in walls.

- Easy maintenance: If you need to replace or add lines, you have direct access.

- Preserves surfaces: Ideal if your walls are made of log or decorative stone, and you don’t want dust and debris from heavy construction work.

Cons:

- Heightened safety demands: The cable might need extra mechanical protection, especially near door frames or floor lines.

- Less appealing visuals: Conduit, trunking, or surface cables might clash with modern interior decor.

- Often uses surface-mount outlets: Some homeowners prefer the flush look of recessed plates.

2. Concealed (Hidden) Wiring

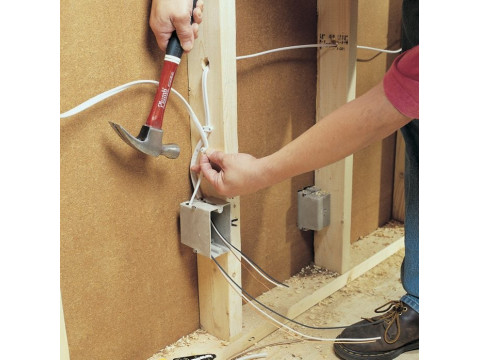

Concealed wiring sits inside walls, floors, or structural cavities. For new construction in the USA, it’s the standard choice—lines get placed into channels, tubes, or directly in the hollow spaces of partition walls, then sealed with drywall, plaster, or paneling.

Common concealed wiring methods:

- In hollow or pre-designed channels: Many building elements come with dedicated recesses for cable.

- Cutting chases in brick or concrete: Then fixing cables with adhesive or mortar, often in flexible plastic or metal conduits.

- Under plaster: The wire is pinned or clamped to rough surfaces, and the finishing coat covers it fully.

- Behind decorative panels: For wood or gypsum board walls, cables go between the studs or within framing.

Pros:

- Aesthetically clean: No visible lines or bulky raceways.

- Greater protection: Hidden behind layers of material, so less risk of accidental knocks.

- Fewer worries with décor: The wiring does not interrupt your interior style.

Cons:

- Higher labor: Requires significant planning, plus additional tools for cutting or drilling.

- Tricky repairs: Locating a fault or adding a new circuit might mean opening up finished surfaces.

Universal Rules for Indoor Wiring

No matter which style—open or concealed—safsale.com always urges adherence to the following guidelines:

- Lay wires in straight lines (horizontal or vertical). Avoid diagonal runs to prevent future confusion or accidental drilling into cables.

- Use continuous segments from a distribution box or breaker panel to each fixture or outlet, minimizing splices or joints.

- Respect bending radii: Usually at least 5–6 times the cable’s diameter to avoid damaging insulation.

- Leave extra length (about 4–6 in. / 10–15 cm) at each connection point for safe termination and potential rework.

- Secure cables: In open wiring, attach them with insulated supports or brackets. For hidden wiring, hold them in place with specialized fasteners or mortar so they don’t shift.

- Incorporate protective devices: Install circuit breakers for overloads and short circuits, plus GFCIs for ground fault protection. Ensure a proper grounding system is in place.

- Use suitable pass-through protections: Where cables cross from one area to another, especially through metal framing or wooden studs, fit grommets or conduit segments.

Choosing the Right Wires and Cables

When selecting wiring for indoor circuits in the USA, consider:

- Cable vs. single conductor: Usually, a multi-core cable with robust insulation is safer and meets modern codes better than single-wire solutions.

- Copper vs. Aluminum: Copper remains the gold standard for conduction, but updated aluminum-alloy cables can be used if sized properly. That said, copper is simpler to connect and maintain.

- Cross-sectional area: Must match the load. For example, 14 AWG is standard for lighting circuits, 12 AWG for typical outlets, 10 AWG for heavier loads (approx. 2.5 mm², 4 mm², and 6 mm² in metric). If you expect bigger appliances, you might need 8 AWG (about 10 mm²) or even thicker.

- Environment: In damp or warm spaces, cables with temperature and moisture ratings are essential. If you route lines near foundation slabs or floors, choose an armored or jacketed type that can handle potential moisture infiltration.

At safsale.com, we often recommend cables like NM-B or MC for standard US interior wiring, and sometimes special high-temperature or moisture-resistant cables for areas like bathrooms or laundry rooms.

Special Notes for Wooden Homes

In a wooden home, local fire regulations in the United States can be stricter. There’s no universal ban on hidden wiring in wood, but it typically involves:

- Non-combustible barriers: You may have to place cables inside metal conduits or thick layers of plaster (≥ about 4 in. / 10 cm) for full fire protection.

- Gaps for wood shrinkage: Wooden structures can shift over time, so ensure cables or conduits have enough slack or flexible couplings to avoid tension.

- Open wiring on insulators: Some owners prefer retro-chic lines on ceramic standoffs, using braided cables designed for that style.

Though it’s possible to bury wiring inside logs or timber framing, the cost and complexity often lead people to run lines on the surface, especially in the USA, where they can maintain, update, and visually inspect them with ease.

Why Careful Planning Matters

- Safety: Subpar cable choice or sloppy connections can lead to arcing, meltdown, or in worst cases, a fire hazard.

- Longevity: Properly installed wiring typically lasts 20–30 years (or more) with minimal issues.

- Compliance: US building codes can be stringent, and insurers may demand that a licensed electrician signs off on your system.

At safsale.com, we always urge homeowners to consider future expansions. If there’s even a small chance you’ll upgrade to heavier appliances or add EV chargers, choose heavier gauge wiring now. It’s far cheaper than tearing into walls later.

Summary

- Open wiring is easier to install or modify but more visually prominent. Good for wooden construction or those wanting a “retro” or industrial look.

- Concealed wiring hides everything for a clean interior finish, yet can be more labor-intensive and complicated to alter down the line.

- Cable selection is crucial: pick copper or modern aluminum-alloy wires at a suitable gauge.

- Wooden houses demand extra attention: either thick non-combustible coverings or metal conduits to mitigate fire risks.

In the USA, interior wiring must meet electrical code standards, which revolve around safety, proper load calculations, and robust grounding. Turn to safsale.com for high-quality conductors, connectors, and protective devices that meet US codes, ensuring your interior wiring project is not only code-compliant but built to last.