Induction Motor Starting Methods: Efficient Techniques

Induction motors are widely used in industries due to their reliability, efficiency, and simple design. However, starting an induction motor requires careful management to prevent high inrush currents and mechanical stresses.

This article explores various motor starting methods, their advantages, disadvantages, and applications to help select the best approach for different industrial needs.

1️⃣ Direct-On-Line (DOL) Start

🔹 How It Works

In a DOL start, the motor is directly connected to the power supply without any starting device. This method is the simplest and most cost-effective.

🔹 Advantages

✔ Simple and easy to implement

✔ Low initial cost

✔ High starting torque

🔹 Disadvantages

❌ High starting current (5-7 times the rated current)

❌ Potential voltage dips in the power network

❌ Mechanical stress on motor components

📌 Best For: Small motors (below 5 HP) where high inrush current is acceptable.

2️⃣ Star-Delta (Y-Δ) Starter

🔹 How It Works

- The motor starts in star (Y) mode, reducing voltage to 1/√3 (approximately 58% of full voltage).

- After reaching ~80% of rated speed, it switches to delta (Δ) mode for full voltage operation.

🔹 Advantages

✔ Reduces starting current by ~67%

✔ Lower mechanical stress

✔ Cost-effective for medium-sized motors

🔹 Disadvantages

❌ Requires six winding connections (not all motors support it)

❌ Momentary torque drop during transition

❌ Limited control over starting characteristics

📌 Best For: Medium-power motors (10-100 HP) in pumps, fans, and conveyors.

3️⃣ Auto-Transformer Starter

🔹 How It Works

- Uses an auto-transformer to apply reduced voltage (50-80% of full voltage) during startup.

- After startup, the motor runs at full voltage.

🔹 Advantages

✔ Lower starting current compared to DOL

✔ Higher torque compared to star-delta

✔ Smooth transition to full speed

🔹 Disadvantages

❌ Requires additional transformer equipment

❌ Higher cost than star-delta

📌 Best For: Large motors in compressors, fans, and industrial machinery.

4️⃣ Soft Starter (Thyristor-Based)

🔹 How It Works

- A soft starter gradually increases voltage using thyristors (SCRs), limiting inrush current and mechanical stress.

- After the motor reaches full speed, the soft starter bypasses itself to avoid additional power losses.

🔹 Advantages

✔ Smooth acceleration, reducing stress on the motor

✔ Reduces starting current (typically 2-3x rated current)

✔ Ideal for delicate mechanical systems

🔹 Disadvantages

❌ More expensive than DOL or star-delta starters

❌ No speed control after startup

📌 Best For: Pumps, fans, and conveyor belts, where gradual acceleration is necessary.

5️⃣ Variable Frequency Drive (VFD) Start

🔹 How It Works

- A VFD converts AC power to DC, then back to AC with adjustable voltage and frequency.

- The motor starts at low frequency and voltage, gradually increasing to the required speed.

🔹 Advantages

✔ Best energy efficiency (reduces power consumption)

✔ Precise speed and torque control

✔ Eliminates inrush current problems

🔹 Disadvantages

❌ High initial cost

❌ Requires complex installation and programming

📌 Best For: Applications requiring variable speed control, such as HVAC systems, conveyors, and elevators.

6️⃣ Reactor Start

🔹 How It Works

- Uses series reactors (inductors) to limit inrush current during motor startup.

- After startup, the reactors are bypassed.

🔹 Advantages

✔ Simple and reliable

✔ Reduces starting current (up to 2-3x rated current)

🔹 Disadvantages

❌ Reduces starting torque

❌ Requires additional space for reactors

📌 Best For: Medium-sized motors where space isn’t an issue.

7️⃣ Capacitor Start (For Single-Phase Motors)

🔹 How It Works

- A capacitor is connected in series with the start winding to create phase shift, producing higher starting torque.

- After startup, the capacitor is disconnected.

🔹 Advantages

✔ Improves starting torque

✔ Reduces voltage drop during startup

🔹 Disadvantages

❌ Requires large capacitors for effective operation

❌ Not used in three-phase systems

📌 Best For: Single-phase motors, such as those used in household appliances and small pumps.

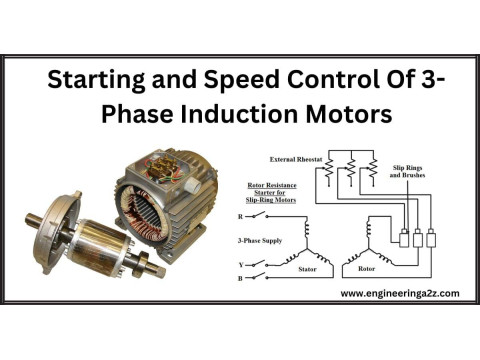

8️⃣ Rheostat (Resistor) Start

🔹 How It Works

- Additional resistors are inserted into the rotor circuit (for wound rotor motors) to limit startup current.

- The resistors gradually reduce resistance as speed increases.

🔹 Advantages

✔ High starting torque

✔ Smooth acceleration

🔹 Disadvantages

❌ Requires external resistors, adding complexity

❌ Lower efficiency due to energy loss in resistors

📌 Best For: Cranes, hoists, and heavy-duty industrial equipment.

9️⃣ Reversing Start (Reversal of Motor Rotation)

🔹 How It Works

- In three-phase motors, reversing two phase wires changes the direction of the rotating magnetic field, reversing the motor.

- In single-phase motors, a reversing switch alters the capacitor connection.

🔹 Advantages

✔ Quick and effective for bidirectional applications

✔ Simple electrical configuration

🔹 Disadvantages

❌ Sudden reversal can stress mechanical components

❌ Requires interlocking systems to prevent simultaneous forward/reverse operation

📌 Best For: Cranes, conveyors, and lathe machines requiring bidirectional motion.

Comparison of Motor Starting Methods

| Starting Method | Current Reduction | Torque Control | Speed Control | Cost | Best For |

|---|---|---|---|---|---|

| Direct-On-Line (DOL) | ❌ High | ❌ No | ❌ No | ✅ Low | Small Motors |

| Star-Delta | ✅ Medium | ❌ Limited | ❌ No | ✅ Medium | Pumps, Fans |

| Auto-Transformer | ✅ Medium | ✅ Yes | ❌ No | ❌ High | Compressors |

| Soft Starter | ✅ Medium | ✅ Yes | ❌ No | ❌ High | HVAC, Pumps |

| VFD | ✅ Best | ✅ Best | ✅ Yes | ❌ High | Variable Speed Applications |

| Reactor Start | ✅ Medium | ❌ No | ❌ No | ✅ Low | Medium Motors |

| Capacitor Start | ✅ Medium | ✅ Yes | ❌ No | ✅ Low | Single-Phase Motors |

| Rheostat Start | ✅ High | ✅ Yes | ❌ No | ❌ High | Heavy-Duty Machines |

Final Thoughts on Induction Motor Starting

Choosing the right induction motor starting method depends on power rating, load characteristics, and budget.

📌 Key Takeaways:

✔ DOL - Simple but high starting current

✔ Star-Delta - Reduces current for medium motors

✔ Soft Starter - Smooth acceleration with reduced stress

✔ VFD - Best for energy savings & speed control

⚡ Need an efficient motor startup solution? Choose the best starting method to optimize performance and longevity!