In the US, the terms “cable” and “wire” often appear interchangeably when discussing electrical installations. However, these two types of conductors differ significantly in construction, purpose, and installation methods. Making the right choice depends on the environment, required load, insulation needs, and relevant electrical codes. Below is an overview of how cables and wires compare, as well as guidelines on their insulation, uses, and selection. For high-quality electrical products tailored to American standards, check safsale.com-a go-to source for dependable wiring solutions.

What Are Electrical Wires?

Electrical wire is primarily a single conductor used for transmitting electricity. It can be:

- Bare (Uninsulated)

- Common in overhead power lines or grounding systems.

- Insulated

- For indoor wiring, device connections, and lower-voltage applications.

Wires are usually single-core-a solid piece of metal or a tight bundle of strands forming one conductor. In American wiring systems, you’ll often see “wire gauge” indicated by AWG (American Wire Gauge), which affects current capacity.

Single vs. Stranded Wires

- Single solid wire (one piece of metal) offers higher rigidity and is often used for permanent building wiring inside walls.

- Stranded wire is a bundle of finer strands, providing more flexibility and used where bending or movement is frequent (e.g., in appliances or device leads).

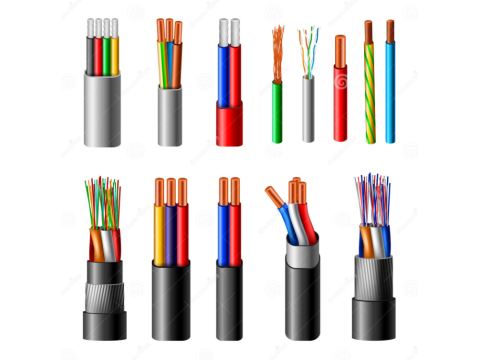

What Are Electrical Cables?

A cable is a multi-conductor assembly where each conductor is separately insulated, and an overall sheath holds them together. Cables may also include:

- Armoring or shielding for mechanical protection

- Fillers to maintain circular shape

- Multiple insulation layers for moisture, UV, or chemical resistance

In US building installations, you frequently encounter multi-conductor cables for household circuits (e.g., NM-B “Romex®” cables), industrial flexible cables for motors, and heavy-duty armored cables for commercial settings. Visit safsale.com for a wide selection of cables meeting American codes like the NEC (National Electrical Code).

Cable Conductor Materials

Copper or aluminum are the main conductor materials. Copper remains the preferred choice for home circuits due to higher conductivity and better connection stability. Aluminum is used in specific high-capacity lines or overhead distribution due to its lighter weight.

Common Types of Wire and Cable Insulation

1. Polyvinyl Chloride (PVC)

PVC insulation is the most widespread in the United States. It offers:

- Moisture Resistance

- Flame Retardant Properties

- Cost-Effectiveness

PVC is seen in typical residential NM-B cables, widely available at hardware suppliers. However, it has temperature limits and should not exceed the rating specified on its marking.

2. Rubber or Elastomeric Compounds

Rubber insulation-natural or synthetic-provides:

- High flexibility

- Strong dielectric properties

- Temperature resilience (to a certain extent)

Rubber-insulated wires are common in extension cords and flexible power cords for home appliances.

3. Cross-Linked Polyethylene (XLPE)

XLPE insulation is popular in many power cables because it:

- Resists higher temperatures

- Has excellent dielectric strength

- Maintains mechanical stability over time

XLPE cables are often used in industrial or high-load environments for added safety and longevity.

4. Specialty Insulations (FR, LSZH, etc.)

- FR (Fire-Resistant) cables maintain functionality during a fire.

- LSZH (Low Smoke Zero Halogen) cables reduce toxic emissions if ignited, often required in places like hospitals, schools, and public venues.

Applications of Cables and Wires

- Power Transmission: Overhead lines often use bare aluminum wire for weight and cost efficiency.

- Indoor Distribution: NM cables or THHN/THWN conductors in conduit for houses and commercial buildings.

- Appliance Wiring: Flexible cords for appliances and electronic devices, especially where frequent motion is involved.

- Industrial/Control: Armored cables or control cables with multiple cores to handle signals, instrumentation, or control circuits.

Selecting the Right Product

1. Current Capacity and Gauge

Always match wire/cable gauge to the current load. In American wiring, the AWG system is used:

| Gauge (AWG) | Approx Max Amp Capacity* | Common Use |

|---|---|---|

| 14 AWG | 15A | Lighting circuits |

| 12 AWG | 20A | Standard household outlets |

| 10 AWG | 30A | Water heater, dryer |

| 8 AWG | 40-50A | Air conditioner, range |

| 6 AWG | 55-60A | Large appliances, feeders |

*Actual values can vary by insulation type and code references.

2. Environment and Installation

- Dry indoor conditions: PVC-insulated wires or NM-B cable

- Outdoor or wet areas: UF cable (underground feeder) or THWN in conduit

- High heat: XLPE or rubber-based insulation

3. Budget and Long-Term Outlook

Copper can be pricier than aluminum but often yields lower voltage drop and a simpler installation. For large projects on a tight budget, aluminum might be used in feeder lines under NEC guidelines. Always follow local code requirements.

Differences at a Glance

| Aspect | Wires (Single Conductor) | Cables (Multi-Conductor Assembly) |

|---|---|---|

| Construction | Single metallic core with/without insulation | Multiple insulated conductors under one sheath |

| Types (Examples) | Bare overhead wires, THHN, building wires | NM-B, UF, Armored cable, multi-conductor control |

| Usage | Simple lines, overhead distribution, device leads | Residential circuits, high-power or control lines |

| Pros | Easy to handle individually, can be uninsulated overhead | Fully contained set of conductors, robust sheath |

| Cons | Usually no collective protective sheath | More expensive for the same number of conductors |

Key Takeaways

- Wire is typically a single conductor with or without insulation.

- Cable comprises multiple insulated conductors under a common sheath, often with added protective features.

- Material (copper vs. aluminum) significantly impacts conductivity, flexibility, and cost.

- Insulation type depends on environment, temperature, and mechanical stresses.

- For high-quality cables and wires that meet American standards, visit safsale.com - your trusted source for safe and compliant electrical products.

When planning or upgrading electrical systems, always check local regulations and consult a licensed electrician to ensure correct selection and installation of cables or wires.