Understanding Synchronous Motors and Their Operation

Synchronous motors are a type of AC motor where the rotor speed matches the frequency of the stator’s magnetic field. They are widely used in industrial applications that require precise speed control and high efficiency.

This article explores the structure, working principle, advantages, and different starting methods of synchronous motors.

1️⃣ What is a Synchronous Motor?

A synchronous motor operates at a constant speed, determined by the supply frequency, according to the formula:

Where:

- = Synchronous speed (RPM)

- = Supply frequency (Hz)

- = Number of poles

Unlike induction motors, which operate with a slip, synchronous motors run at a fixed speed regardless of load variations.

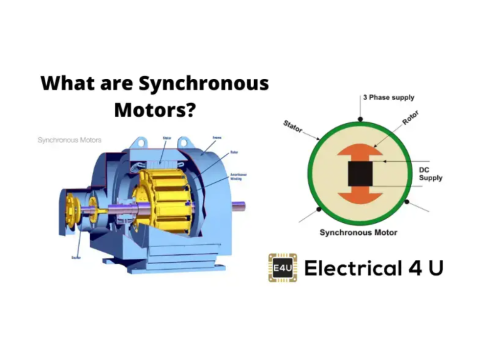

2️⃣ Construction of a Synchronous Motor

A synchronous motor consists of the following key parts:

🔹 Stator (Stationary Part)

- Contains a three-phase winding

- Produces a rotating magnetic field (RMF) when powered

🔹 Rotor (Rotating Part)

- Can be either wound (with field windings) or permanent magnet-based

- Creates its own magnetic field

🔹 Excitation System

- Provides DC excitation to the rotor field winding

- Can be supplied via slip rings and brushes or brushless excitation

🔹 Contact Brushes (For Wound Rotor Motors)

- Conducts DC current to the rotor winding

- Permanent magnet motors do not need brushes

🔹 Frame & Bearings

- Provides mechanical support

- Ensures smooth rotation of the rotor

3️⃣ Working Principle of a Synchronous Motor

1️⃣ When AC power is applied, the three-phase stator windings create a rotating magnetic field (RMF).

2️⃣ The rotor receives DC excitation, creating a magnetic field.

3️⃣ The rotor locks in with the stator’s magnetic field and starts spinning at synchronous speed.

4️⃣ The motor maintains this speed as long as the load does not exceed its pull-out torque.

📌 Unlike induction motors, synchronous motors do not rely on slip for torque generation.

4️⃣ Types of Synchronous Motors

| Motor Type | Excitation Type | Application |

|---|---|---|

| Wound Rotor | Uses DC excitation | Large industrial machines, compressors |

| Permanent Magnet (PMSM) | Uses permanent magnets | Robotics, aerospace, precision control |

| Reluctance Motor | Rotor designed with saliency | Fans, pumps, automation systems |

| Hysteresis Motor | Uses magnetic hysteresis effects | Clocks, record players, small loads |

📌 Permanent Magnet Synchronous Motors (PMSMs) are gaining popularity due to their high efficiency and reliability.

5️⃣ Advantages of Synchronous Motors

✔ Constant Speed Operation – No slip, precise speed control

✔ High Efficiency – Less energy loss compared to induction motors

✔ Power Factor Correction – Can operate at leading power factor, reducing grid demand

✔ Better Load Handling – Can handle overload for short durations

🚀 Common Uses: HVAC systems, compressors, elevators, industrial conveyors

6️⃣ Challenges of Synchronous Motors

❌ Complex Starting Process – Cannot self-start like induction motors

❌ Higher Initial Cost – Requires excitation system

❌ Maintenance Required – Brush-based systems need regular servicing

📌 Solution: Use electronic controllers (VFDs) or advanced starter circuits for smooth operation.

7️⃣ How to Start a Synchronous Motor

Since synchronous motors cannot self-start, different methods are used for smooth acceleration:

🔹 1. Using an Auxiliary Motor

- A separate small induction motor starts the rotor.

- Once near synchronous speed, DC excitation is applied.

- The motor locks into synchronous operation.

📌 Used in large industrial applications.

🔹 2. Damper Winding (Asynchronous Start)

- Rotor has additional short-circuited windings (like an induction motor).

- During startup, the motor runs like an induction machine.

- Once close to synchronous speed, DC excitation is applied to lock in synchronization.

📌 Used in high-power industrial motors.

🔹 3. Variable Frequency Drive (VFD) Start

- The best modern solution for soft starting.

- VFD gradually increases frequency from 0 Hz to rated speed.

- Benefits:

✔ Eliminates high inrush currents

✔ Allows speed control and energy savings

📌 Used in HVAC systems, elevators, and precision control applications.

8️⃣ Synchronous vs Induction Motor: Key Differences

| Feature | Synchronous Motor | Induction Motor |

|---|---|---|

| Operating Speed | Fixed (No slip) | Varies with load |

| Self-Starting | ❌ No | ✅ Yes |

| Efficiency | ✅ High | ✅ Moderate |

| Power Factor | ✅ Adjustable (Can be leading) | ❌ Always lagging |

| Cost | ❌ Higher | ✅ Lower |

| Maintenance | ❌ Requires excitation system | ✅ Lower maintenance |

📌 Best Choice:

- Induction Motors → General-purpose applications

- Synchronous Motors → High-precision, high-power applications

9️⃣ Applications of Synchronous Motors

📌 Where precise speed control and high efficiency are required:

✔ Industrial Compressors & Pumps – Large HVAC systems, water supply stations

✔ Milling & Grinding Machines – Cement & mining industries

✔ Conveyor Systems – Automated manufacturing plants

✔ Power Plants – Used as synchronous condensers for power factor correction

🔟 Conclusion: Choosing the Right Motor

📌 Key Takeaways:

✔ Synchronous motors run at a fixed speed, making them ideal for applications requiring precise control.

✔ They require an external excitation system and advanced starting techniques like damper windings or VFDs.

✔ They improve power factor, reducing industrial energy costs.

⚡ Looking for energy-efficient motor solutions? Synchronous motors offer unmatched efficiency and stability for demanding applications!