Ultrasonic Sensors: Level and Motion Solutions

Ultrasound refers to sound waves at frequencies above 20 kHz—well beyond human hearing. In practical sensor designs, engineers often use frequencies around 100–400 kHz to detect liquids or moving objects without physical contact. By analyzing how these high-frequency waves travel, reflect, or shift, ultrasonic sensors enable you to:

- Measure liquid or material levels inside tanks, silos, or wells

- Detect motion using the Doppler effect

Below, we’ll explore how ultrasonic sensors work for level measurement, how they detect movement, and what makes them so reliable in dusty or challenging conditions. For more US-focused advice—brand recommendations, code compliance, or wiring best practices—check safsale.com, where you’ll find in-depth resources on ultrasonic sensor integration.

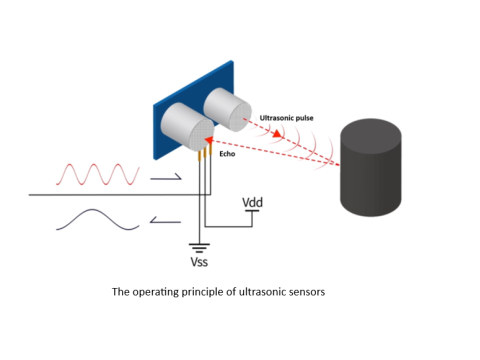

1. How Ultrasonic Sensors Work

1.1 Basics of Ultrasound

High-frequency sound waves propagate through air, liquids, or solids. Key properties include:

- Speed of sound in the medium

- Attenuation (energy loss as waves travel)

- Reflection or scattering when waves meet surfaces

Sensors emit a short pulse or continuous signal from a transducer, then listen for the echo. By measuring time or phase difference, the electronics can compute distance or detect motion.

2. Ultrasonic Level Sensors

2.1 Diffuse-Type (Common for Level Measurement)

Often referred to as distance-measuring or echo-based sensors:

- The sensor’s transmitter emits a brief ultrasonic pulse.

- The pulse reflects off the liquid surface.

- A receiver (often the same transducer) detects the return echo.

- The device calculates the distance from the travel time.

Common operating ranges can vary widely, from about 2–30 cm minimum to several meters maximum. For instance:

- A model like UM30-15111 might measure from 800 mm up to 8000 mm (approx. 80 cm to 8 m).

- Another, UM30-11113, could sense 30–350 mm range.

Obviously, you can’t have a single sensor that provides perfect coverage from a few centimeters all the way to 10 meters. If your application needs both extremely close and far-distance readings, you might install two overlapping sensors.

2.2 Reflective or “Retroreflective”

These use an additional reflector placed in the path, improving detection accuracy by comparing the echo from a fixed reflector with the echo from the fluid or object. Such configurations reduce random error but require careful alignment with the reflector.

2.3 Through-Beam Designs

A separate transmitter and receiver mount facing each other, creating an ultrasonic “barrier.” This is typical for linear or “beam” detection. It’s not as common for level measurement but can see use in manufacturing lines to sense items passing between transmitter and receiver.

2.4 Output Types

- Analog (voltage or current): Proportional to the measured distance or level

- Digital: Communicates via binary or protocol-based signals

- Switch/Threshold: On/off output at specified level

Ultrasonic level sensors are prized for their non-contact operation, mechanical simplicity, and potential for high accuracy (around ±1%). They handle dirty or wet atmospheres well since their wave energy generally isn’t blocked by moderate dust or mist.

3. Ultrasonic Motion Detectors (Doppler)

When used for motion detection, ultrasonic sensors typically rely on the Doppler effect. Similar to microwave motion detectors:

- The sensor emits a constant ultrasonic wave.

- Movement within the coverage area shifts the frequency of the returning wave.

- The sensor circuit detects this shift, triggering an “object in motion” signal.

3.1 Coverage and Sensitivity

- Typical maximum range: Up to 10 meters indoors.

- Detection zone: Often a volumetric area shaped like an elongated ellipse.

- Surfaces can absorb or reflect ultrasound to different degrees. Materials like foam or thick carpeting might reduce effective range.

3.2 Key Advantages

- Less susceptible to light or thermal interference, unlike IR-based sensors.

- Immune to electromagnetic fields, making them ideal for certain industrial settings.

- Detect movement in dusty or dimly lit areas without difficulty.

One drawback: Ultrasonic waves can pass through thin walls or ceilings, potentially causing false alarms from adjacent rooms. Proper sensor placement is crucial.

4. Benefits of Ultrasonic Sensors

- Accuracy and Reliability

- High precision for level measurement (±1%).

- Detects movement even in dusty or smoky conditions.

- No Moving Parts

- Minimal mechanical wear, leading to long service life and low maintenance.

- Versatility

- Measure liquid levels or identify solid objects passing by.

- Wide range of available distances—short to several meters.

- Immunity to Light and Temperature

- Not affected by bright lights or minor temperature fluctuations the way IR sensors can be.

5. Key Applications in the USA

- Water or Fuel Tanks: Continuous monitoring for refilling or pumping out.

- Municipal / Industrial: Sewage lift stations, chemical tanks, or open channels.

- Security Systems: Intrusion detection in warehouses or perimeter fences.

- Smart Parking: Ultrasonic modules track distance to walls or other vehicles.

- Automated Doors or Lighting: Occupancy detection in hallways or entry points.

6. Selection Considerations

When picking an ultrasonic sensor, ask:

- Range: Minimum and maximum distances needed.

- Environmental: Does dust, vapor, foam, or wind complicate measurements?

- Output: Analog, digital, or simple threshold switching?

- Mounting: Top-down or side mounting? Horizontal or angled approach?

- Housing and IP Rating: Are you dealing with moisture, high pressure, or chemical exposure?

For more advanced details—like US-based brand offerings or code compliance—explore safsale.com. You’ll find guidelines on sensor wiring, robust enclosures, and matching transducer frequencies to your specific environment.

Conclusion

Ultrasonic sensors excel in non-contact measurement—be it for continuous liquid levels or motion detection. By analyzing echoes or Doppler shifts, these devices deliver:

- Reliable distance measurement in water tanks, sumps, or production lines

- Accurate movement detection in security or automation setups

They’re robust against factors that plague other sensor types (like dust or lighting changes) and often require minimal maintenance. Correct selection—factoring in range, environment, and the needed output—ensures an efficient, long-lasting solution.

Remember: If you handle foam, heavy vapors, or extremely high distances, confirm your sensor model is rated for those conditions. With the right choice, you’ll enjoy a dependable, trouble-free system for measuring fluid levels or detecting motion, all thanks to ultrasonic technology.