Electromagnetic Locks are a pivotal component in modern Access Control and Management Systems (ACMS), providing robust security solutions for residential, commercial, and industrial applications. These locks offer a seamless and keyless entry method, ensuring that only authorized individuals can access restricted areas. Known for their reliability and strength, electromagnetic locks are widely used in conjunction with other security devices such as surveillance cameras, controllers, and access card readers to form comprehensive security infrastructures. This guide explores the design, selection, installation, functionalities, and best practices for electromagnetic locks within ACMS, ensuring optimal security and compliance with American standards.

Understanding Electromagnetic Locks for Access Control Systems

Electromagnetic locks, commonly referred to as Maglocks, are locking devices that use electromagnetic force to secure doors. They are integral to ACMS, enabling controlled access to various premises by restricting entry to authorized personnel only. These locks are favored for their simplicity, strength, and ease of integration with electronic security systems.

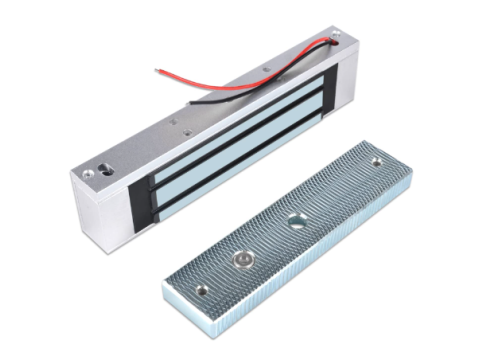

Key Components

- Electromagnet: Mounted on the door frame, this component generates a magnetic field when energized.

- Armature Plate (Yarmo): Attached to the door, it is attracted to the electromagnet, creating a strong hold that keeps the door closed.

- Control Unit: Manages the lock’s operation, receiving signals from access control devices.

- Power Supply: Provides the necessary electrical energy to operate the electromagnet.

- Protective Diodes: Installed to protect against voltage spikes and ensure stable operation.

Types and Features of Electromagnetic Locks

Electromagnetic locks vary based on their installation methods, functionalities, and applications. The primary types include:

1. Recessed Electromagnetic Locks

Overview

Recessed Electromagnetic Locks are installed within the door itself, with the locking mechanism concealed inside. This setup enhances security by making the lock less visible and more resistant to tampering.

Advantages

- Enhanced Security: Concealed mechanism reduces vulnerability to tampering.

- Aesthetic Appeal: Maintains a clean door appearance without visible lock components.

- Durability: Protected from external elements, ensuring long-term reliability.

Disadvantages

- Complex Installation: Requires precise fitting and professional installation.

- Limited Flexibility: Modifying or upgrading the lock necessitates significant door alterations.

2. Surface-Mounted Electromagnetic Locks

Overview

Surface-Mounted Electromagnetic Locks consist of two main parts: the electromagnet and the armature plate, both mounted on the door’s surface and frame. This type is easier to install compared to recessed locks.

Advantages

- Ease of Installation: Simple mounting process without the need for door modification.

- Versatility: Suitable for various door types, including metal and wooden doors.

- Cost-Effective: Generally less expensive due to simpler installation requirements.

Disadvantages

- Lower Security: More susceptible to tampering since components are exposed.

- Aesthetic Impact: Visible components may detract from door design aesthetics.

3. Sway-Type Electromagnetic Locks

Overview

Sway-Type Electromagnetic Locks are designed for sliding doors or gates. They provide secure access control for openings that move horizontally rather than swinging.

Advantages

- Specialized Use: Ideal for sliding doors, ensuring secure locking without hindering door movement.

- High Holding Force: Capable of securing heavy doors and gates with significant holding strength.

Disadvantages

- Installation Complexity: Requires precise alignment to ensure smooth operation.

- Higher Cost: Often more expensive due to specialized design features.

Principles of Operation and Design

Working Principle

Electromagnetic locks operate on the principle of electromagnetic force. When the lock is energized, the electromagnet creates a magnetic field that attracts the armature plate, securing the door in a locked position. The door remains locked as long as power is supplied. Upon receiving a command from the access control system (e.g., authorized card swipe or remote signal), the power is cut, releasing the magnetic hold and allowing the door to open.

Design Features

Fail-Safe Operation:

- Unlock on Power Loss: Designed to automatically unlock when power is interrupted, ensuring safety during emergencies like fires.

- Integration with Fire Alarms: Can be configured to release locks automatically in response to fire alarm signals, facilitating safe evacuation.

Code Flexibility:

- Remote Operation: Allows for remote unlocking and locking via controllers or smart devices.

- Multiple User Access: Supports various access methods, including keycards, biometrics, and PIN codes.

Holding Force:

- Measurement: The strength of the lock’s hold is measured in kilograms or pounds, determining its suitability for different door types and security needs.

- Selection: Choose a lock with adequate holding force based on door material and expected usage.

Selecting and Installing Electromagnetic Locks

Selection Criteria

Choosing the right electromagnetic lock involves evaluating several factors to ensure compatibility, security, and functionality:

Door Type and Material:

- Metal Doors: Require locks with higher holding force due to their weight and sturdiness.

- Wooden Doors: May need lower holding force but should still ensure reliable security.

Holding Force:

- High Traffic Areas: Opt for locks with higher holding force (e.g., 500 kg) to manage frequent use.

- Residential Use: Lower holding force (e.g., 150-300 kg) is typically sufficient.

Installation Type:

- Recessed vs. Surface-Mounted: Decide based on aesthetic preferences, security requirements, and door compatibility.

Power Supply:

- Voltage Requirements: Most locks operate at 12V or 24V. Ensure the power supply matches the lock’s specifications.

- Backup Power: Implement Uninterruptible Power Supplies (UPS) or batteries to maintain lock functionality during power outages.

Integration Capabilities:

- Access Control Systems: Ensure compatibility with existing or planned ACMS components, such as controllers and card readers.

- Smart Home Integration: Choose locks that can integrate with smart home ecosystems for enhanced control and monitoring.

Brand Reputation and Reviews:

- Reliable Manufacturers: Opt for reputable brands known for quality and durability, such as Kerberos, Nora-M, and Mettäm.

- Customer Feedback: Review user experiences to gauge performance and reliability.

Installation Steps

Proper installation is crucial to ensure the electromagnetic lock operates effectively and securely. Follow these steps for a successful installation:

1. Preparation

- Gather Tools and Materials:

- Screwdrivers, drills, measuring tape, mounting brackets, screws, and the electromagnetic lock kit.

- Marking:

- Determine the exact position for the lock on the door and frame. Use precise measurements to ensure proper alignment.

2. Mounting the Lock

Electromagnet Installation:

- Positioning: Mount the electromagnet on the door frame at a height that aligns with the armature plate on the door.

- Securing: Use mounting brackets and screws provided in the kit to secure the electromagnet firmly.

Armature Plate Installation:

- Positioning: Attach the armature plate to the door, ensuring it aligns perfectly with the electromagnet.

- Securing: Use screws or bolts to secure the armature plate, ensuring it remains in place during door movement.

3. Wiring and Power Supply

- Connecting to Power:

- Connect the electromagnetic lock to the designated power supply, ensuring correct polarity and secure connections.

- Integrating with ACMS:

- Connect the lock to the access control system’s controller, following the manufacturer’s wiring diagrams.

- Installing Protective Components:

- Diodes: Install protective diodes to manage inductive spikes and ensure stable operation.

- Capacitors: Use capacitors to reduce residual magnetism and improve lock release times.

4. Configuring the Control Unit

- Programming Access Controls:

- Set up authorized access methods, such as keycards, PIN codes, or biometric scanners, through the ACMS controller.

- Testing Functionality:

- Test the lock’s response to access commands, ensuring it engages and disengages correctly.

- Adjustments:

- Make any necessary adjustments to alignment or settings based on test results to ensure optimal performance.

5. Finalizing Installation

- Concealing Wiring:

- Use cable concealers or conduits to protect wiring from tampering and maintain aesthetic appeal.

- Securing and Inspecting:

- Conduct a thorough inspection to ensure all components are securely installed and functioning correctly.

Best Practices

Professional Installation:

- While some installations can be DIY, hiring a professional ensures precise alignment and optimal security.

Regular Maintenance:

- Periodically inspect the lock for signs of wear, alignment issues, or electrical problems.

- Clean and lubricate components to maintain smooth operation.

Secure Power Supply:

- Use dedicated power circuits for ACMS components to prevent interference and ensure system stability.

- Implement backup power solutions to maintain lock functionality during outages.

Code Management:

- Regularly update access codes to maintain security and prevent unauthorized access.

- Implement a system for revoking or changing codes when authorized users no longer require access.

Integration with Other Security Systems:

- Combine electromagnetic locks with surveillance cameras, alarm systems, and motion detectors for comprehensive security coverage.

User Training:

- Educate authorized users on proper usage and management of the ACMS to maintain system integrity.

Advantages and Disadvantages of Electromagnetic Locks

Advantages

- High Security:

- Provides a strong and reliable hold, making unauthorized entry difficult.

- Keyless Entry:

- Eliminates the need for physical keys, reducing the risk of lost or stolen keys.

- Aesthetic Appeal:

- Minimalistic design without visible keyholes or bulky components enhances door appearance.

- Durability:

- Lack of moving parts ensures long-term reliability and resistance to wear and tear.

- Integration Capabilities:

- Easily integrates with various access control methods, including keycards, biometrics, and smart devices.

- Automatic Operation:

- Can be configured to automatically lock and unlock based on access commands, enhancing convenience and security.

Disadvantages

- Dependence on Power Supply:

- Requires continuous power to remain locked. In the event of a power outage, the door remains unlocked, posing security risks.

- Installation Complexity:

- Precise alignment is necessary to ensure proper functioning, often requiring professional installation.

- Limited Mechanical Security:

- Unlike traditional mechanical locks, electromagnetic locks do not offer a physical barrier against forced entry beyond the magnetic hold.

- No Physical Barrier:

- Does not provide substantial physical resistance against forced entry attempts.

- Maintenance Requirements:

- Electrical components may require regular maintenance to ensure optimal performance and prevent failures.

Compliance with Standards and Regulations

Ensuring that your electromagnetic locks comply with relevant standards is essential for safety, reliability, and legal adherence.

Relevant Standards

- NFPA 72 - National Fire Alarm and Signaling Code:

- Governs the design, installation, and maintenance of fire alarm and signaling systems, including aspects related to ACMS integration.

- National Electrical Code (NEC):

- Regulates the electrical aspects of alarm system installations to ensure safety and compliance.

- UL Standards:

- Provide safety and performance requirements for security alarm devices and components.

- OSHA Standards (29 CFR 1910):

- Include fire safety regulations for workplaces, covering the installation and maintenance of fire alarm systems to protect employees.

- Local Building Codes:

- Additional requirements specific to your locality must also be adhered to for compliance and safety.

Key Compliance Points

- Power Supply Design:

- Ensure all power supplies meet the electrical requirements outlined in NEC and UL standards, including proper grounding and protection mechanisms.

- Cable Management:

- Adhere to guidelines for cable routing, minimizing exposure and protecting against physical damage or tampering.

- System Integration:

- Ensure that all ACMS components are correctly integrated with other security and safety systems for coordinated operation.

- Data Protection:

- Comply with data privacy laws such as the California Consumer Privacy Act (CCPA) to protect biometric and other sensitive data.

- Emergency Power Solutions:

- Implement backup power systems (e.g., UPS, batteries) in compliance with NFPA 72 to ensure system functionality during emergencies.

Final Thoughts

Electromagnetic Locks are essential for modern Access Control and Management Systems (ACMS), offering a blend of electronic control and robust security features to safeguard premises effectively. Understanding the different types of electromagnetic locks, selecting the appropriate lock based on specific needs, ensuring proper installation, and adhering to best practices are crucial steps in enhancing the security of any facility. Additionally, compliance with relevant standards and regular maintenance will ensure the longevity and effectiveness of your electromagnetic locks.

Key Takeaways:

Choose the Right Lock Type: Assess your security requirements and door compatibility to determine whether recessed, surface-mounted, or sway-type electromagnetic locks are most suitable.

Ensure Reliable Power Supply: Implement stable and backup power solutions to maintain lock functionality during power outages, especially for fail-safe applications.

Prioritize Proper Installation: Follow best practices for mounting, wiring, and configuring electromagnetic locks to ensure optimal performance and security.

Implement Regular Maintenance: Schedule routine inspections and maintenance to sustain the longevity and reliability of electromagnetic locks.

Manage Access Effectively: Regularly update access codes and manage user permissions to maintain security and prevent unauthorized access.

Combine with Other Security Measures: Integrate electromagnetic locks with other security systems like surveillance cameras and alarm systems for comprehensive protection.

Adhere to Standards: Ensure all installations comply with relevant electrical and building codes to guarantee safety and legal compliance.

Professional Assistance: Consider hiring certified security professionals for installation and maintenance to ensure electromagnetic locks operate effectively and securely.

Backup Access Methods: Provide alternative methods for unlocking doors in case of lock failure or power outages, enhancing overall security and user convenience.

User Training: Educate authorized users on proper usage and management of the access control system to maintain system integrity.

For expert assistance in selecting and installing electromagnetic locks for access control systems, ensuring compliance with relevant standards, or accessing comprehensive project documentation, visit safsale.com. Our specialists are ready to help you design and deploy reliable, compliant, and efficient access control solutions tailored to your specific security needs.

Important Notice on Standards

All referenced documents and standards in this guide are provided for informational purposes only and should not be used as official publications. For authoritative guidelines and legal requirements, always consult the official standards organizations or regulatory bodies.