A capacitive sensor measures changes in electrical capacitance to detect the presence or absence of objects, liquids, or other materials. From position detection to level measurement, these sensors exploit the principle that a capacitor’s properties shift when its environment changes. Below, we outline how capacitive sensors are constructed, their primary working principles, and the versatility they bring to automation and control systems.

1. Principle of Operation

1.1 Capacitance Basics

Capacitance refers to a conductor’s ability to store electric charge when a voltage is applied. In standard electronic terminology, a capacitor consists of two conductive plates (or electrodes) separated by a dielectric medium. Its capacitance depends on:

- Plate Area (A)

- Distance (d) between plates

- Dielectric Constant (ε) of the material between them

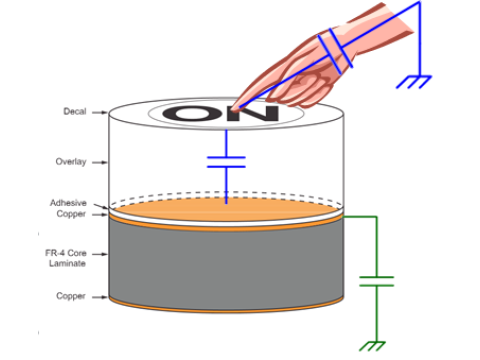

A capacitive sensor creates an electric field around a plate (or electrode). Introducing or removing another material in this electric field-such as a human hand, a piece of metal, or a liquid-alters the sensor’s capacitance. When this change surpasses a threshold, the sensor’s circuitry triggers an output signal.

1.2 Key Elements

A typical capacitive sensor includes:

- Electrode or Plate: Forms the “active” element where the electric field emanates.

- Housing and Electronics: Contain the signal processing board, which detects capacitance changes and provides a usable output.

- Ground or Reference Surface: In some setups (like large metal surfaces or floors), these can serve as a reference electrode.

2. Capacitive Position (Proximity) Sensors

2.1 How They Detect Objects

Capacitive proximity sensors use an electrode that projects an electric field into the surrounding space. When an object with a different dielectric constant than air (virtually anything solid or liquid) comes near, it changes the field distribution, causing a measurable rise in capacitance. The sensor’s circuitry detects this increase and switches its output.

- Detection Range: Typically from a few millimeters up to a few centimeters, determined by sensor design and target dielectric properties.

- Advantages:

- Can detect various materials (metal, plastic, wood, glass, etc.)

- No moving parts

- Good reliability in clean environments

- Challenges:

- Sensitive to electromagnetic interference and environmental factors

- Limited sensing distance compared to some other sensor types

2.2 Applications

- Proximity Detection: In manufacturing lines, to sense parts on conveyors or to confirm that an object is present in a mold.

- Contactless Switches: Touch-activated buttons (like elevator panels or home appliances).

- Security Systems: Some alarm devices sense a hand or body approaching a metal object, triggering an alert.

3. Capacitive Level Sensors

3.1 Monitoring Liquids and Bulk Solids

By placing two electrodes (or a single rod/cylindrical probe against a vessel wall), the sensor measures how much of the electrode is immersed in a material. The material’s dielectric constant differs from air, causing a shift in capacitance when levels rise or fall.

- Design Variations:

- Parallel Plates or Coaxial Cylinders for tank installations

- Rod-Style Probes for vertical measurements

- Output Types:

- Threshold (On/Off): Switches when the material crosses a certain level

- Continuous Measurement: Delivers an analog or digital signal proportional to the fill percentage

3.2 Benefits

- High Accuracy: Suitable for precise level control in liquids or powders

- No Moving Mechanical Parts: Reduces maintenance

- Versatility: Adapts easily to many container shapes or materials

3.3 Considerations

- Dielectric Constant: Variation in fluid composition (e.g., water vs. oil) affects accuracy

- Installation Environment: Ensuring the sensor withstands temperature or pressure extremes if used in industrial tanks

- Multi-Level Configurations: Placing multiple probes at different heights for multi-point detection

4. Other Capacitive Sensor Applications

- Tilt Sensors: By allowing a fluid to shift between two plates, changes in overlap area measure tilt angles.

- Rotational/Speed Detection: As rotating plates alter the overlapping area, the sensor can track angular position or velocity.

- Smartphone Touchscreens: Rely on capacitive sensing to detect finger contact across a grid of electrodes.

5. Practical Insights for Selection and Setup

- Environmental Noise: Capacitive sensors can be prone to electromagnetic interference (EMI). Proper shielding and grounding improve reliability.

- Distance and Resolution: For short-range detection, capacitive sensors excel. If you need long-range, consider ultrasonic or optical alternatives.

- Mounting Material and Surface: Metal surfaces, humidity, or dust might affect the sensor’s field. Check manufacturer guidelines regarding spacing or protective housings.

- Required Output Type: Some applications only need a simple switch output (on/off), while others benefit from analog feedback or more advanced digital communication.

Conclusion

A capacitive sensor leverages changes in capacitance to detect physical alterations-from objects entering its proximity to fluid level changes inside a tank. Its wide applicability spans industrial automation, liquid level monitoring, and everyday touch-activated devices. While these sensors offer significant advantages-like detecting various material types and featuring minimal mechanical wear-proper selection and careful EMI mitigation can be pivotal to success.

For expert help in choosing or integrating capacitive sensors in your automation, safety, or measurement projects, safsale.com provides tailored solutions. By understanding your operating environment, sensing distance needs, and signal requirements, these versatile sensors ensure reliable, precise detection across numerous applications.