Categories of Automatic Circuit Breakers: Understanding Types A, B, C, D, K, and Z

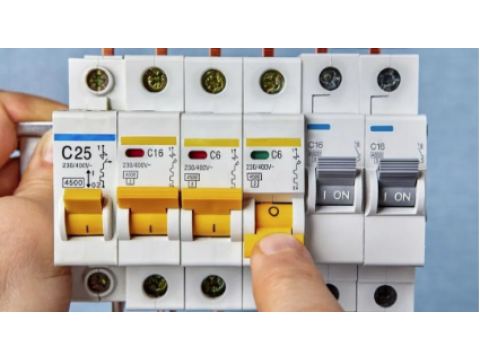

Introduction to Categories of Automatic Circuit Breakers

Automatic Circuit Breakers (ACBs) are essential devices in electrical systems, designed to protect circuits and connected equipment from overloads and short circuits. One of the primary ways to classify these breakers is based on their tripping characteristics, denoted by letters such as A, B, C, D, K, and Z. Understanding these categories is crucial for selecting the appropriate breaker that matches the specific demands of your electrical network, ensuring both safety and efficiency.

Types A, B, C, D, K, and Z Automatic Circuit Breakers

Automatic Circuit Breakers are classified into different types based on the ratio of the current that causes them to trip relative to their nominal (In) current. These types determine how sensitive the breaker is to overcurrent conditions and help prevent unnecessary trips while ensuring adequate protection against electrical faults.

1. Type A Circuit Breakers

Purpose:

Type A circuit breakers are designed to trip when the current exceeds 2 to 3 times the nominal current (In).

Applications:

- Non-Inductive or Lightly Inductive Loads: Suitable for circuits without significant inrush currents, such as lighting and heating systems.

- Residential Use: Rarely used in household applications due to the high likelihood of false tripping.

Characteristics:

- Trip Range: 2In to 3In

- Usage Frequency: Infrequent due to high sensitivity, leading to potential nuisance trips.

Recommendation:

Type A breakers are seldom used in residential settings because typical household loads do not usually cause such high inrush currents. They are more suitable for specialized applications where minimal overcurrent scenarios are expected.

2. Type B Circuit Breakers

Purpose:

Type B circuit breakers trip when the current exceeds 3 to 5 times the nominal current (In).

Applications:

- Active Load Circuits: Ideal for circuits with non-inductive or lightly inductive loads that do not experience significant inrush currents.

- Residential Homes and Apartments: Commonly used for general-purpose circuits where large motors or heavy inductive loads are absent.

Characteristics:

- Trip Range: 3In to 5In

- Usage Frequency: Widely used in residential applications due to balanced sensitivity and protection.

Recommendation:

Type B breakers are suitable for lighting circuits, electrical heaters, and other similar applications where the electrical load remains relatively stable without large inrush currents.

3. Type C Circuit Breakers

Purpose:

Type C circuit breakers trip when the current exceeds 5 to 10 times the nominal current (In).

Applications:

- Moderately Inductive Loads: Perfect for circuits that include devices like refrigerators, washing machines, air conditioners, and other appliances with moderate inrush currents.

- General-Purpose Circuits: Versatile enough for a wide range of household and commercial applications.

Characteristics:

- Trip Range: 5In to 10In

- Usage Frequency: The most commonly used type due to its versatility and ability to handle typical household appliance loads without frequent tripping.

Recommendation:

Type C breakers are ideal for general-purpose outlets and circuits where moderate inductive loads are present, providing reliable protection without unnecessary interruptions.

4. Type D Circuit Breakers

Purpose:

Type D circuit breakers trip when the current exceeds 10 to 20 times the nominal current (In).

Applications:

- Highly Inductive Loads: Suitable for circuits with large motors, compressors, welding machines, and other equipment that cause significant inrush currents.

- Industrial and Heavy-Duty Applications: Essential for environments where electrical machinery frequently experiences high starting currents.

Characteristics:

- Trip Range: 10In to 20In

- Usage Frequency: Less common in residential settings but essential for industrial applications to prevent false tripping during heavy load starts.

Recommendation:

Type D breakers are essential for circuits powering large motors and heavy machinery, ensuring protection against sustained high currents without unnecessary tripping.

5. Type K Circuit Breakers

Purpose:

Type K circuit breakers are designed for specific applications that require handling even higher inrush currents, typically beyond the standard ranges of Types A to D.

Applications:

- Specialized Industrial Equipment: Used in environments with exceptionally high inrush currents, such as large industrial motors and high-capacity transformers.

- Rare Residential Applications: Not commonly used in standard residential setups.

Characteristics:

- Trip Range: Beyond 20*In

- Usage Frequency: Rare and highly specialized due to the extreme current levels they are designed to handle.

Recommendation:

Type K breakers are reserved for specialized industrial applications where standard breakers cannot provide the necessary protection against extremely high inrush currents.

6. Type Z Circuit Breakers

Purpose:

Type Z circuit breakers are another specialized category, designed for niche applications that require unique protection characteristics not covered by Types A to D and K.

Applications:

- Custom Industrial Applications: Used in environments with unique electrical demands or unconventional equipment.

- Highly Specific Use Cases: Rarely encountered outside of specialized industrial settings.

Characteristics:

- Trip Range: Custom ranges tailored to specific application needs.

- Usage Frequency: Extremely rare and highly specialized.

Recommendation:

Type Z breakers are utilized in very specific and uncommon industrial scenarios where other types do not meet the protection requirements.

Electrical Characteristics and Recommended Applications

Understanding the electrical characteristics of each breaker type is crucial for selecting the appropriate circuit breaker for your specific needs. The key parameters include:

- Nominal Current (In): The rated current that the breaker can handle continuously without tripping.

- Trip Curve: Defines the relationship between the overcurrent level and the time it takes for the breaker to trip.

- Instantaneous Tripping: Achieved by exceeding the nominal current by several multiples, determined by the breaker type.

Trip Curves Explained

The trip curve is a graphical representation that shows how quickly a breaker will trip based on the level of current overload. The horizontal axis represents the multiple of the nominal current (I/In), while the vertical axis represents the time to trip.

- Type A: Trips between 2In and 3In

- Type B: Trips between 3In and 5In

- Type C: Trips between 5In and 10In

- Type D: Trips between 10In and 20In

Example: For a Type C breaker with a nominal current of 16A:

- Trip Range: 80A to 160A (516A to 1016A)

This means the breaker will trip almost instantaneously if the current exceeds 80A to 160A, depending on the exact trip curve.

Applications of Different Categories of Automatic Circuit Breakers

Proper selection of breaker categories based on their tripping characteristics ensures optimal protection and minimizes the risk of false tripping. Here’s how each type is typically applied:

1. Type A Circuit Breakers

Purpose:

Designed for circuits with active loads that do not produce significant inrush currents.

Applications:

- Lighting Systems: Protects lighting circuits from overloads without tripping during normal operation.

- Heating Elements: Safeguards electric heaters and radiant floor systems where inrush currents are minimal.

- General Outlets: Suitable for outlets powering non-inductive appliances.

Recommendation:

Type A breakers are best used in scenarios where electrical loads are steady and do not involve large motors or compressors that cause high inrush currents.

2. Type B Circuit Breakers

Purpose:

Trips at 3-5 times the nominal current, suitable for circuits without large inductive loads.

Applications:

- Residential Homes and Apartments: Ideal for general-purpose circuits where high inrush currents are unlikely.

- Light Appliance Circuits: Protects outlets and lighting where occasional moderate inrush currents may occur.

- Non-Inductive Loads: Suitable for circuits powering devices that do not have significant starting currents.

Recommendation:

Type B breakers are versatile and commonly used in residential applications, offering a balance between protection and minimizing nuisance trips.

3. Type C Circuit Breakers

Purpose:

Trips at 5-10 times the nominal current, making them the most common and versatile type.

Applications:

- Household Appliances: Protects devices like washing machines, refrigerators, vacuum cleaners, and air conditioners that have moderate inrush currents.

- Office Equipment: Safeguards computers, printers, and other electronic devices that may experience occasional current spikes.

- General-Purpose Circuits: Suitable for a wide range of residential and commercial applications.

Recommendation:

Type C breakers are the most widely used due to their adaptability and ability to handle typical household and office appliance loads without frequent tripping.

4. Type D Circuit Breakers

Purpose:

Trips at 10-20 times the nominal current, designed for circuits with high inductive loads.

Applications:

- Industrial Machinery: Protects large motors, compressors, and heavy-duty machinery that cause significant inrush currents.

- Welding Machines: Safeguards equipment with high starting currents.

- Industrial and Commercial Buildings: Suitable for environments with substantial electrical loads and equipment requiring robust protection.

Recommendation:

Type D breakers are essential for industrial applications where high inrush currents are common, ensuring that the breaker provides adequate protection without false trips.

5. Type K Circuit Breakers

Purpose:

Designed for specialized applications requiring handling of exceptionally high inrush currents.

Applications:

- Large Industrial Equipment: Protects extremely high-capacity motors and transformers.

- Specialized Industrial Processes: Suitable for environments with unique electrical demands.

Recommendation:

Type K breakers are used in highly specialized industrial settings where other breaker types cannot provide the necessary protection against extreme inrush currents.

6. Type Z Circuit Breakers

Purpose:

Another specialized category for niche applications with unique protection requirements.

Applications:

- Custom Industrial Applications: Used in scenarios with unconventional electrical setups or specialized equipment.

- Highly Specific Use Cases: Rarely used outside of specific industrial environments.

Recommendation:

Type Z breakers are employed in very particular industrial scenarios where standard breaker types do not meet the protection needs.

Electrical Characteristics and Selection Criteria

When selecting an automatic circuit breaker, consider the following key electrical characteristics and criteria to ensure optimal protection and performance:

1. Nominal Current (In)

- Definition: The rated current that the breaker can handle continuously without tripping.

- Selection: Choose a breaker with a nominal current that matches or slightly exceeds the maximum expected load of the circuit.

- Example: For a circuit requiring 16A, select a breaker with a nominal current of 16A.

2. Trip Curve

- Description: Defines the relationship between the overcurrent level and the trip time, categorized as Types A, B, C, D.

- Selection: Choose a trip curve type based on the nature of the load to ensure reliable protection without unnecessary trips.

- Type B: For non-inductive or lightly inductive loads.

- Type C: For general-purpose circuits with moderate inductive loads.

- Type D: For circuits with high inductive loads.

3. Voltage Rating (Un)

- Definition: The maximum voltage the breaker can safely interrupt.

- Selection: Ensure the voltage rating of the breaker matches the operating voltage of your electrical system (e.g., 120V, 240V).

4. Operating Voltage Type

- Types: Single-phase or three-phase breakers.

- Selection: Choose based on the electrical system configuration in your home or facility.

5. Number of Poles

- Definition: The number of separate circuits the breaker can protect (e.g., single-pole, double-pole).

- Selection: Depends on the circuit design and the level of protection required.

- Single-Pole: Interrupts only the live (L) wire.

- Double-Pole: Interrupts both live (L) and neutral (N) wires, enhancing safety by ensuring both conductors are disconnected simultaneously.

6. Physical Dimensions

- Considerations: Ensure the breaker fits within the electrical panel’s available space.

- Compatibility: Check compatibility with existing panel configurations and mounting standards, such as DIN rail mounting.

7. Environmental Conditions

- Temperature Range: Most breakers operate optimally between 0°C to 40°C.

- Humidity and Exposure: Choose breakers with appropriate ratings for environments with high humidity or exposure to dust and moisture (e.g., IP ratings).

Practical Example: Selecting an Automatic Circuit Breaker

Scenario:

You have a residential electrical circuit with a conductor size of 2.5 mm², which is typically rated for a maximum current of 25A.

Steps:

Calculate the Nominal Current:

- Maximum load based on conductor size: 25A.

Select the Trip Curve:

- For a typical residential load with minimal inductive devices, a Type B breaker is appropriate.

Choose the Correct Nominal Current:

- To prevent overheating, select a breaker with a nominal current lower than the conductor’s maximum rating.

- Recommended Breaker: 16A.

Verify Compatibility:

- Ensure the 16A breaker fits within your electrical panel and matches the panel’s specifications.

Finalize Selection:

- Choose a high-quality breaker from reputable brands like Siemens, Schneider Electric, or ABB to ensure reliability and safety.

Outcome:

By selecting a 16A Type B breaker, you ensure that the conductor is protected from overloads while avoiding nuisance tripping during normal operation. Additionally, using a reputable brand guarantees long-term performance and compliance with safety standards.

Installation Diagrams for Automatic Circuit Breakers

Properly connecting automatic circuit breakers is crucial for ensuring the safety and functionality of your electrical system. Below are the primary connection schemes for ACBs in a single-phase network, typically used in private homes and apartments.

1. Single-Pole and Double-Pole Connection Schemes

Single-Pole Connection:

- Description: The breaker interrupts only the live (L) wire.

- Diagram Reference: (Figure 1)

- Setup:

- Phase (L): Connected to one pole of the breaker.

- Neutral (N): Connected directly to the neutral bus without interruption.

- Advantages: Cost-effective and saves space in the distribution panel.

- Disadvantages: If the neutral and live wires are mistakenly swapped, the breaker will not fully disconnect the circuit, leaving the neutral connected.

Double-Pole Connection:

- Description: The breaker interrupts both the live (L) and neutral (N) wires.

- Diagram Reference: (Figure 2)

- Setup:

- Phase (L) and Neutral (N): Both connected to the breaker poles.

- Neutral Bus: Only one contact is connected to the neutral bus at the supply side.

- Advantages: Ensures complete disconnection of both conductors, enhancing safety by eliminating the risk of live-neutral swapping.

- Disadvantages: More expensive and occupies more space in the distribution panel.

Recommendation:

For most residential applications, a single-pole connection is sufficient and more economical. However, in scenarios where maximum safety is paramount, such as in critical circuits or high-risk environments, a double-pole connection is preferable.

2. Connecting the Automatic Circuit Breaker to the Electricity Meter

When integrating an electricity meter (Счетчик) into your distribution panel, there are two primary methods to connect the main breaker:

Method 1: Before the Meter

- Advantages:

- Simplifies maintenance and repairs by allowing safe work on all circuits, including the meter.

- Disadvantages:

- Increases the risk of unauthorized connections for energy theft.

- Utility companies may require sealing or locking the main breaker terminals to prevent tampering.

Method 2: After the Meter

- Advantages:

- Prevents unauthorized access since the meter's terminals are typically sealed by the utility company.

- Enhances security by ensuring the main breaker cannot be easily tampered with.

- Disadvantages:

- Requires separate protection for the distribution panel since the main breaker cannot disconnect the meter.

Recommended Approach:

Connecting the main breaker after the meter is generally preferred by utility providers to prevent energy theft. This method ensures that the meter remains secured and tamper-proof.

Connection Schemes in the Distribution Panel

Beyond the main breaker and meter connections, the distribution panel includes various protection devices such as:

- Branch Circuit Breakers: Protect individual circuits for lighting, outlets, and high-power appliances.

- Residual Current Devices (RCDs): Detect and disconnect circuits experiencing current leakage.

- Differential Circuit Breakers (Differential Automats): Combine the functions of branch circuit breakers and RCDs for comprehensive protection.

- Voltage Relays: Protect equipment from voltage fluctuations.

Example Connection Diagram: Refer to (Figure 3) for a typical connection scheme of automatic circuit breakers within an electrical panel. This diagram illustrates how different protection devices interconnect to safeguard various consumer groups.

Note: Grounding circuits are conditionally omitted in illustrative diagrams. Modern apartments typically include grounding, whereas older buildings might lack this feature. Proper grounding is essential for electrical safety but does not fundamentally alter the connection principles of ACBs.

Practical Considerations for Installing Automatic Circuit Breakers

1. Protecting Lighting Circuits:

For lighting circuits that do not involve high inductive loads, Type B breakers are suitable. They prevent false trips while ensuring protection against overloads and short circuits.

2. Protecting Outlet Circuits:

Outlet circuits, which often power inductive loads like appliances with motors, benefit from Type C breakers. These breakers can handle moderate inrush currents without tripping unnecessarily.

3. Protecting High-Power Appliances:

High-power appliances such as washing machines, electric stoves, and boilers should be connected to dedicated circuits protected by Type D breakers. These breakers accommodate significant inrush currents typical of motor-driven equipment.

Alternative Protection: For high-power appliances, instead of pairing an RCD with a branch breaker, a differential circuit breaker (Differential Automat) can be used. This device provides both overcurrent and leakage protection in a single unit, offering streamlined protection for dedicated circuits.

Conclusion

Understanding the categories of automatic circuit breakers-Types A, B, C, D, K, and Z-is essential for selecting the right breaker that matches your electrical system's requirements. Each type offers unique protection characteristics tailored to different load conditions, ensuring both safety and efficiency. Proper selection, installation, and maintenance of circuit breakers not only safeguard your property but also enhance the overall performance of your electrical appliances and systems.

At safsale.com, we offer a comprehensive range of high-quality automatic circuit breakers from leading manufacturers like Siemens, Schneider Electric, ABB, Eaton, and Hager. Equip your home or business with the best protection solutions to ensure a safe and efficient electrical environment for you and your family.

For more information and to explore our selection of automatic circuit breakers and other electrical protection devices, visit safsale.com