Principle of Operation of Automatic Circuit Breakers

Introduction to Automatic Circuit Breakers

Automatic Circuit Breakers (ACBs) are critical components in modern electrical systems, designed to protect electrical circuits and connected equipment from damage caused by overloads and short circuits. By automatically disconnecting the power supply when abnormal current flows are detected, ACBs prevent potential hazards such as electrical fires, equipment damage, and personal injuries. Understanding the principle of operation of automatic circuit breakers is essential for maintaining a safe and efficient electrical system in your home or workplace.

Purpose of Automatic Circuit Breakers

Protecting Electrical Circuits from Overloads and Short Circuits

The primary purpose of an Automatic Circuit Breaker is to safeguard electrical circuits from two main issues:

- Overloads: Occur when the electrical demand exceeds the circuit's capacity, leading to excessive current flow.

- Short Circuits (СЗ): Happen when a low-resistance path is unintentionally established, causing a sudden surge in current.

Both conditions can severely damage electrical wiring and connected devices, posing significant fire risks. Automatic Circuit Breakers mitigate these risks by swiftly disconnecting the affected circuit, thereby maintaining the integrity and safety of the entire electrical system.

Principle of Operation of Automatic Circuit Breakers

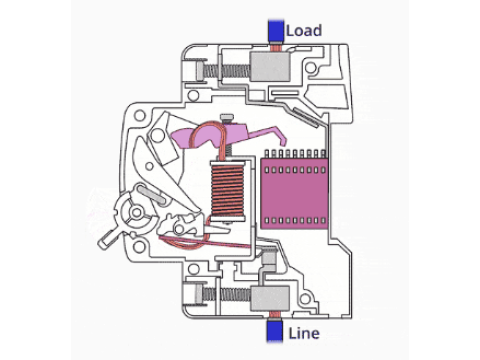

Dual Protection Mechanism: Electromagnetic and Thermal Tripping

Automatic Circuit Breakers operate by monitoring two critical parameters:

- Overcurrent from Short Circuits (КЗ)

- Overload Current

1. Electromagnetic Tripping Mechanism

Purpose:

Electromagnetic Circuit Breakers are designed to protect circuits from short circuits by responding rapidly to sudden increases in current.

How They Work:

- Solenoid Activation: These breakers contain a solenoid (electromagnet) through which the current flows. When the current exceeds a predetermined threshold, the increased magnetic field generated by the solenoid triggers the breaker to trip, opening the circuit.

- Immediate Response: Electromagnetic breakers react almost instantaneously to high current levels, providing swift protection against short circuits.

Characteristics:

- Trip Time: Extremely fast, typically in the order of fractions of a second.

- Current Rating: Available in various ratings to accommodate different circuit requirements.

- Design: Robust and reliable, suitable for both residential and industrial applications.

Applications:

- Residential: Protecting lighting and outlet circuits.

- Commercial: Safeguarding office equipment and HVAC systems.

- Industrial: Ensuring safety in heavy machinery and production lines.

2. Thermal Tripping Mechanism

Purpose:

Thermal Circuit Breakers are intended to protect electrical circuits from overloads by disconnecting the power when the current exceeds safe levels over an extended period.

How They Work:

- Bimetallic Strip: These breakers use a bimetallic strip that bends when heated by excessive current. The bending motion triggers the breaker to trip, opening the circuit.

- Delayed Response: Unlike electromagnetic breakers, thermal breakers respond to prolonged overcurrent conditions, providing protection against sustained overloads without reacting to short, transient surges.

Characteristics:

- Trip Time: Slower response compared to electromagnetic breakers, designed to handle continuous overcurrent without nuisance tripping.

- Current Rating: Available in various ratings to match different circuit capacities.

- Design: Typically simpler and more cost-effective, suitable for standard residential applications.

Applications:

- Residential: Protecting household appliances and lighting circuits.

- Commercial: Safeguarding office electrical systems and equipment.

- Light Industrial: Protecting smaller machinery and tools.

Trip Curves: Types B, C, D

Automatic Circuit Breakers are categorized based on their trip curves, which define the relationship between the level of overcurrent and the time it takes for the breaker to trip. The main types include:

- Type B: Trips at 3-5 times the nominal current (In).

- Type C: Trips at 5-10 times the nominal current (In).

- Type D: Trips at 10-20 times the nominal current (In).

Nominal Current (In):

The rated current at which the breaker can continuously operate without tripping. Selection of trip curve type depends on the nature of the electrical load:

- Type B: Suitable for circuits with non-inductive or lightly inductive loads, such as lighting and heating.

- Type C: Ideal for general-purpose circuits with moderate inductive loads, such as receptacles and small appliances.

- Type D: Best for circuits with highly inductive loads, such as large motors and industrial machinery.

How to Choose the Right Automatic Circuit Breaker

Selecting the appropriate Automatic Circuit Breaker involves evaluating several factors to ensure it meets your specific safety and performance needs:

1. Determine the Circuit’s Load

- Calculation: Assess the total electrical load of the circuit by summing the wattage of all connected devices.

- Formula:

- Example: For a 240V circuit with a total load of 3000W,

- Selection: Choose a breaker with a nominal current slightly higher than the calculated value, typically the next standard size (e.g., 15A).

2. Consider the Type of Load

- Inductive Loads: Devices like motors and compressors that have high starting currents.

- Recommendation: Use Type C or D breakers to accommodate inrush currents without nuisance tripping.

- Resistive Loads: Devices like lighting and heating elements with steady currents.

- Recommendation: Type B breakers are suitable for these applications.

3. Select the Appropriate Trip Curve

- Understanding: Choose a trip curve based on the nature of the load to ensure reliable protection.

- Type B: Suitable for lighting and small appliance circuits.

- Type C: Ideal for general-purpose circuits with moderate inductive loads.

- Type D: Best for circuits with high inductive loads, such as industrial machinery.

4. Match the Voltage Rating

- Ensure: The breaker’s voltage rating matches the operating voltage of your electrical system (e.g., 120V, 240V).

5. Check Physical Compatibility

- Measure: Confirm that the breaker fits within the electrical panel’s dimensions.

- Compatibility: Ensure the breaker is compatible with the panel’s manufacturer and model.

6. Evaluate Environmental Conditions

- Assess: Consider the installation environment to choose a breaker with appropriate durability and protection against environmental factors like dust, moisture, and temperature extremes.

Practical Example: Selecting an Automatic Circuit Breaker

Scenario: You have a residential electrical circuit with a conductor size of 2.5 mm², which is typically rated for a maximum current of 25A.

Steps:

Calculate the Nominal Current:

- Maximum load based on conductor size: 25A.

Select the Trip Curve:

- For a typical residential load with minimal inductive devices, a Type B breaker is appropriate.

Choose the Correct Nominal Current:

- To prevent overheating, select a breaker with a nominal current lower than the conductor’s maximum rating.

- Recommended Breaker: 16A.

Verify Compatibility:

- Ensure the 16A breaker fits within your electrical panel and matches the panel’s specifications.

Finalize Selection:

- Choose a high-quality breaker from reputable brands like Siemens, Schneider Electric, or ABB to ensure reliability and safety.

Outcome: By selecting a 16A Type B breaker, you ensure that the conductor is protected from overloads while avoiding nuisance tripping during normal operation. Additionally, using a reputable brand guarantees long-term performance and compliance with safety standards.

Applications of Different Types of Automatic Circuit Breakers

Automatic Circuit Breakers are utilized based on their trip curves and the specific requirements of electrical circuits. Here's how different types are applied:

1. Type B Breakers

Purpose:

Designed for circuits with active loads that do not produce significant inrush currents.

Applications:

- Lighting Systems: Protects lighting circuits from overloads.

- Heating Elements: Safeguards electric heaters and radiant floor systems.

- General Outlets: Suitable for outlets powering non-inductive appliances.

2. Type C Breakers

Purpose:

Suitable for circuits with moderate inductive loads that may experience occasional inrush currents.

Applications:

- Receptacle Circuits: Ideal for standard household outlets.

- Small Appliances: Protects devices like refrigerators, washing machines, and air conditioners.

- Office Equipment: Safeguards computers, printers, and other electronic devices.

3. Type D Breakers

Purpose:

Designed for circuits with high inductive loads that cause significant inrush currents.

Applications:

- Large Motors: Protects industrial motors and heavy-duty machinery.

- Soldering Machines: Safeguards equipment with high starting currents.

- Industrial Applications: Suitable for environments with substantial electrical loads and equipment.

Classification of Automatic Circuit Breakers

Automatic Circuit Breakers (ACBs) are classified based on various criteria to ensure they meet specific protection and operational requirements:

1. Application Areas

- Main (Vodno) Circuit Breakers: Installed in the main distribution board (водно распределительном устройстве - ВРУ) to protect the entire electrical system.

- Branch (Line) Circuit Breakers: Operate on individual lines to protect specific groups of consumers, such as lighting circuits, receptacle circuits, and high-power appliances.

2. Nominal Current (In) and Voltage (Un)

- Nominal Current (In): The rated current at which the breaker can continuously operate without tripping.

- Voltage Rating (Un): The maximum voltage the breaker can safely interrupt.

3. Degree of Protection (IP Rating)

- IP Rating (International Protection): Determines the breaker’s resistance to dust and moisture ingress.

- Example: IP65 indicates complete protection against dust and low-pressure water jets.

4. Mounting Method

- DIN Rail Mounted: Designed to be installed on standardized DIN rails within electrical panels.

- Surface Mounted: Mounted directly onto the surface of electrical enclosures.

- Flush Mounted: Installed within electrical panels for a streamlined appearance.

Conclusion

Automatic Circuit Breakers are indispensable for maintaining the safety and integrity of electrical systems in homes, apartments, and cottages across the USA. By understanding their principle of operation, types (electromagnetic and thermal), trip curves (B, C, D), and classification criteria, homeowners can make informed decisions to enhance electrical safety and prevent potential hazards. Proper selection, installation, and maintenance of circuit breakers not only safeguard property but also ensure the efficient operation of electrical appliances and systems.

At safsale.com, we offer a comprehensive range of high-quality automatic circuit breakers from leading manufacturers like Siemens, Schneider Electric, Leviton, ABB, Eaton, and Hager. Equip your home with the best protection solutions to ensure a safe and efficient electrical environment for you and your family.

For more information and to explore our selection of electrical protection devices, visit safsale.com