Pressure Switch for Pump: Installation, Adjustment, and Maintenance

A pressure switch for a pump is an automatic regulator that manages the operation of pump equipment in water supply systems. This device plays a crucial role in maintaining stable water pressure, ensuring comfortable water usage in both residential and industrial settings.

What Does a Pressure Switch Do?

The primary function of a pressure switch is to automatically turn the pump on when the system pressure drops below a set minimum and switch it off when the maximum pressure is reached. This ensures optimal conditions for the entire water supply system, prevents pump overloads, and promotes energy efficiency.

In modern water systems, this device has become indispensable, significantly enhancing ease of use and extending the pump's lifespan.

How a Pressure Switch Works

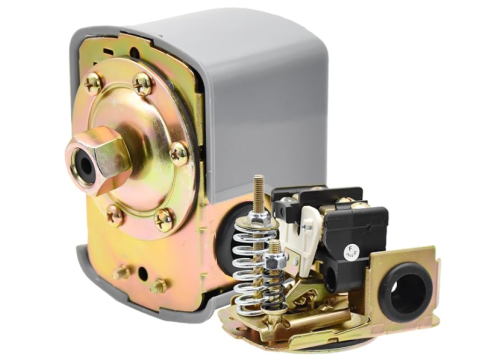

Inside the durable, corrosion-resistant housing-often made from brass, stainless steel, or high-grade plastic-lies a mechanism of levers and springs that converts water pressure into mechanical motion. High-precision components guarantee reliable performance over time.

The electrical part includes a contact group responsible for switching the pump on and off. These contacts, often made from silver or silver alloys, offer excellent conductivity and resistance to arcing. They are protected from moisture and equipped with terminals for wire connections. Many modern models also feature overload and short-circuit protection.

Operating Principle

The pressure switch operates through the interaction of mechanical and electrical parts:

When water pressure drops, the membrane under spring tension moves, closing the electrical contacts and turning the pump on.

When the system reaches the set maximum pressure, the membrane shifts back, opening the contacts and shutting off the pump.

This process happens automatically, maintaining pressure within the desired range.

Adjusting Pressure Settings

Most modern pressure switches allow you to adjust both the upper and lower activation thresholds using screws or nuts that modify spring tension. This lets you tailor the switch to specific system requirements.

Setting the right differential (the gap between activation and deactivation pressures) is key to preventing frequent pump cycling, which can cause premature wear.

Installation and Connection

When installing a pressure switch:

Place it in an accessible area for easy maintenance and adjustments.

Protect it from direct weather exposure and mechanical damage.

Install it on a horizontal pipe section after the pump.

Include a pressure gauge for monitoring and a check valve to prevent backflow.

Electrical connections should be handled by a qualified professional, following all safety standards. Ensure proper wire gauge, secure insulation, and reliable grounding.

Calibration and Fine-Tuning

Before calibration, determine optimal pressure values based on:

Pump specifications

Water demand at usage points

Plumbing system features

Adjust the switch while the pump is running, using a pressure gauge to set the cut-off pressure first, then the cut-in pressure. Test the system under various conditions and fine-tune as needed.

Maintenance and Troubleshooting

Regular maintenance includes:

Checking mechanical connections

Cleaning contacts

Verifying settings

Monitor the membrane's condition, as it’s a critical component. Replace it if signs of wear appear.

Common issues:

Unstable pump operation

Failure to start or stop automatically

Often, the cause is incorrect settings or worn parts. Check electrical connections, contact conditions, and mechanical integrity. For complex problems, consult a specialist.

Modern Trends and Technologies

Today’s market offers electronic pressure switches with advanced features:

Digital displays

Programmable settings

Integrated dry-run and overload protection

Some models integrate with smart home systems, providing real-time data and predictive maintenance capabilities.

Conclusion

A pressure switch is a key component in modern water supply systems, automating pump operation and enhancing reliability. Advances in technology continue to improve these devices, making them more accurate, durable, and user-friendly.

When choosing and installing a pressure switch, consider the specific conditions of your system and follow the manufacturer’s guidelines to ensure long-term, trouble-free performance.