Introduction: Why Floor Wiring is Gaining Popularity in the USA

Floor wiring-running electrical cables directly underneath floors-is rapidly becoming a preferred solution in many American homes and apartments. Traditional wall-chasing methods often require extensive labor, while overhead installations (such as drop ceilings) might not always fit a homeowner’s design or budget. By contrast, floor wiring offers a potentially simpler path to concealed cables, reduces the need for wall demolition, and can lower overall costs when planned correctly.

At safsale.com, we help homeowners across the USA discover innovative solutions for hidden wiring that meet National Electrical Code (NEC) standards. Below, we’ll explore the benefits, drawbacks, and step-by-step guidelines for installing electrical wiring underneath floors in houses and apartments-covering both wooden and concrete subfloor scenarios.

1. Main Advantages and Drawbacks of Floor Wiring

1.1 Advantages

Reduced Material Costs

- Compared to traditional wall-mounted wiring, some estimates show up to 30% savings if you place outlets roughly 10-14 inches (25-35 cm) above the floor.

- Even compared to wiring above drop ceilings, you might still save 10-15% on cable lengths and labor.

Faster, Easier Installation

- By avoiding wall-chasing or thick plaster layers, you can shorten project timelines significantly-especially in apartments or private homes with concrete or brick walls.

- Many DIY homeowners can lay out basic cabling on their own, then call a certified electrician for final hookups and compliance checks.

Enhanced Safety

- Worried about drilling into hidden wires near the ceiling or upper walls? Floor-based cable routes largely eliminate that concern.

- You’ll have more freedom when mounting curtains, shelves, or heavy fixtures without risking contact with overhead wiring.

1.2 Drawbacks

Complex Repairs

- Fixing or replacing a damaged cable under the floor often means lifting floorboards or breaking into concrete-far from ideal.

- To avoid major demolition, follow best practices:

- Use conduits or flexible conduits (gofro) with at least 60% free space left inside.

- Minimize bends and secure cables firmly (spacing roughly 8 inches (20 cm) in wooden floors and up to 20 inches (50 cm) in concrete).

- This way, if a wire fails, you can pull it out and feed a new one through the same conduit.

Cost of Conduits

- In a wood-framed house, you may need more expensive metal conduit to meet fire-safety requirements and protect cables from rodents.

- The savings on cable length could be offset by the added expense of metal gofro or rigid metal pipes.

2. When and Where Floor Wiring is Most Beneficial

Two common US scenarios make under-floor wiring especially appealing:

New Apartments (New Construction / “Bare Shell”)

- Modern apartments often come with unfinished floors or minimal finishing.

- While installing the final floor (e.g., a concrete screed or leveling compound), you can lay cables underneath, keeping walls intact.

- You’ll still need small chases to bring wires up to outlets, but the total labor and cost drop substantially.

Private, Wood-Framed Homes

- Many American log cabins or timber-framed houses feature a rustic or “country” aesthetic.

- Exposed plastic or metal conduits along the walls can clash with the interior style, while retro wiring is often more expensive.

- Hiding cables under floors is a practical solution to maintain a cohesive design and reduce costs associated with decorative wiring systems.

3. Rules and Installation Guidelines

The biggest challenge in floor wiring is adhering to NEC guidelines-particularly those regarding accessibility to junction boxes and splices. If cables are fully buried under a concrete slab, it’s nearly impossible to access them without destroying the floor. Meanwhile, in wooden floors, you must consider fire safety and the possibility of rodent damage.

3.1 Junction Boxes

- NEC rules typically require junction boxes to remain accessible.

- If you place a junction or branching point under the slab (no direct access), you violate these rules.

- Common solutions include:

- Wall-Mounted Boxes at Floor Level - Marked near the cable exits. It can be unsightly and must be child- and pet-proof.

- Outlet-As-Junction - Connect multiple circuits in the same box as an outlet. If a single cable fails, all outlets “downstream” lose power.

- Ceiling or High-Level Boxes - This eliminates some cost benefits (longer cable runs) but remains code-compliant.

3.2 Wooden Floors Over Joists

- Metal Conduit (steel pipes or gofro) is often recommended in the USA for flammable construction.

- Alternatively, use PVC conduits if fully surrounded by at least 0.4 inch (10 mm) of fire-resistant materials (e.g., gypsum or cement).

- Opt for cables rated for low smoke and flame spread, such as VVGng-LS. In American terms, look for MC cable (metal-clad) or NM-B with a specific fire rating.

- All splices must be done with soldering, crimping, or in approved connectors-no open twists are allowed.

- Thoroughly treat wooden surfaces with fire retardants or universal sealants to reduce flammability.

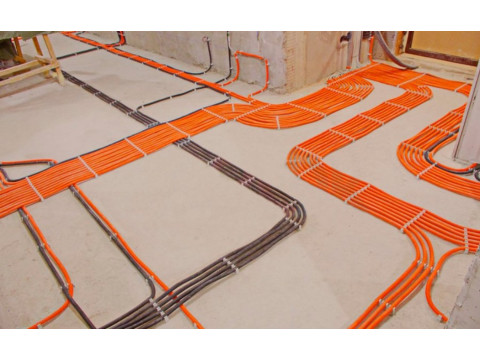

3.3 Concrete Slab Floors (Screed)

Installing cables under a concrete screed is more demanding. Observe the following:

Conduit Integrity

- No breaks or splices in conduits under the slab.

- Each run must be continuous from the exit point to the destination.

Cable Securing

- Fasten cables or conduits firmly to the base or rebar mesh-usually every 16-20 inches (40-50 cm).

- Maintain at least 12 inches (30 cm) from walls and door openings to avoid cracks or future damage.

Heated Floors

- Keep wiring as far as possible from heating elements.

- Use metal conduits if the temperature can rise significantly.

Minimum Screed Thickness

- At least 0.8 inch (20 mm) of screed above the conduit, plus rebar reinforcement.

- Because most conduits have a diameter of about 0.8 inch (20 mm), your total slab thickness might be 1.6 inches (40 mm) or more.

4. Step-by-Step Installation Process

When installing floor wiring in a US home or apartment, follow this sequence:

Mark Outlets and Switches

- Identify exact locations for outlets, switches, and any floor-level junction boxes.

Plan Cable Runs

- Try to prevent crossing lines from different circuits to reduce the total screed thickness.

- If cables must cross, keep them at 90° angles or separate levels.

Measure and Cut Conduits

- Prepare the necessary lengths of PVC or metal conduit.

- Pull cables through them before final placement or after partial placement, ensuring minimal bends.

Secure Cables or Conduits

- Fix them to the subfloor, either with concrete anchors and metal straps or plastic ties to rebar mesh.

- For wooden floors, secure every 8 inches (20 cm); for concrete, every 16-20 inches (40-50 cm).

Pour and Level the Floor

- Apply the chosen screed or install the wooden planks.

- Double-check that conduits remain stable and above the base layer by about 0.2 inch (5-6 mm) if you’re adding a leveling compound.

Wall Chases for Outlets

- After the floor cures, chase or drill minimal channels in walls for routing cables up to the designated outlet or switch height.

Penetrations Through Joists or Walls

- Always run cables through metal sleeves or bushings to prevent insulation damage.

Testing and Verification

- Check phase/neutral continuity and ground connections.

- Test circuits with a multimeter and confirm GFCI/AFCI functionality if required by local codes.

If any cable damage or short circuit is detected, you can attempt to pull a new cable through the conduit without breaking the floor-assuming you’ve kept the conduit free of sharp bends or tight angles.

5. Why Choose SafSale.com for Floor Wiring Solutions in the USA?

At safsale.com, we specialize in US-compliant electrical products that simplify under-floor wiring:

- High-Quality Cables - Including NM-B, MC, and other fire-rated options for both wooden and concrete floors.

- Durable Conduits - PVC, EMT, and metal gofro solutions that meet American safety standards.

- Mounting Accessories - Anchors, clamps, cable ties for secure attachments in any subfloor.

- Expert Assistance - Our team guides you in selecting the right components for your local NEC requirements.

By using safsale.com products, you’ll maximize safety, reduce installation time, and ensure a long-lasting result for your floor wiring system.

Conclusion: A Practical Way to Conceal Wiring in US Homes

Installing electrical wiring under the floor is a modern, efficient, and often cost-saving method for both new and renovated spaces in the USA. While it demands careful attention to fire safety, conduit planning, and code compliance, the payoff can be substantial: fewer wall chases, cleaner interior aesthetics, and simpler expansions or rearrangements in the future.

- Plan thoroughly: Mark cables, minimize bends, and use suitable conduits.

- Meet NEC guidelines: Guarantee proper accessibility to junctions and maintain safe distances from walls and heating elements.

- Factor in local building codes: In wood-framed houses, metal conduits may be mandatory to prevent fire hazards.

Rely on safsale.com for all your floor-wiring needs-high-quality products, code-compliant solutions, and knowledgeable support that helps you confidently undertake any electrical project in your house or apartment. Whether you’re focusing on a wooden subfloor or a concrete slab, we’ve got you covered for a smooth, reliable installation.