Creating optimal thermal conditions is essential for the successful cultivation of plants in greenhouses and nurseries, especially during colder months. Infrared (IR) electric heaters offer a modern, efficient, and safe solution to maintain the necessary microclimate required for plant growth. This guide delves into the principles of infrared heating, the various types of infrared electric heaters, their safety features, advantages, disadvantages, and key factors to consider when selecting the right heater for your greenhouse or nursery.

What Are Infrared Electric Heaters?

Infrared electric heaters are advanced heating devices that emit infrared radiation to warm objects and plants directly, rather than heating the surrounding air. This method closely mimics the natural heating effect of the sun, providing immediate and targeted warmth that enhances plant growth and energy efficiency.

Key Components of Infrared Electric Heaters:

Infrared Emitters:

- Halogen Elements: Utilize gas-filled lamps that emit bright light and IR waves, suitable for industrial applications.

- Quartz Elements: Comprise vacuum tubes with tungsten spirals or carbon fibers, offering versatile heating options.

- Ceramic Elements: Feature resistive cables within ceramic housings, providing robust and efficient heating.

- Carbon Elements: Utilize thermoresistant films or panels with carbon coatings, ideal for flexible and uniform heating.

Reflectors:

- Directional Heat Focus: Concentrate the IR radiation towards specific areas, maximizing heating efficiency.

- Material Composition: Typically made from reflective metals to enhance heat distribution.

Control Systems:

- Thermostats: Allow precise temperature regulation to maintain optimal growing conditions.

- Timers and Programmers: Enable scheduled heating cycles to optimize energy usage.

Principles of Operation

Infrared electric heaters operate based on the fundamental principles of infrared radiation and heat transfer. Understanding these principles is crucial for effectively utilizing IR heaters in greenhouses and nurseries.

1. Radiant Heat Transfer

Direct Heating: Unlike convective heaters that warm the air, IR heaters emit infrared waves that directly heat objects and plants. This method results in higher efficiency, as over 90-95% of the heat energy is absorbed by the targets.

Energy Efficiency: The direct transfer minimizes energy loss, making IR heaters more economical and faster in achieving desired temperatures compared to traditional heating systems.

2. Limited Radius of Action

Inverse Square Law: The intensity of infrared radiation decreases proportionally to the square of the distance from the source. This necessitates strategic placement of heaters to ensure uniform temperature distribution within the greenhouse.

Uniform Distribution: To maintain consistent heating, multiple IR heaters or continuous heating systems (such as warm floors or ceilings) are employed to cover the entire growing area effectively.

Types of Infrared Electric Heaters

Infrared electric heaters come in various types, each designed to cater to specific heating needs and environmental conditions within greenhouses and nurseries.

1. Ceiling Infrared Heaters

Overview

Ceiling-mounted infrared heaters are installed overhead, allowing for unobstructed heat distribution throughout the greenhouse. They are ideal for large-scale operations where floor space is at a premium.

Advantages

- Space-Saving: Frees up floor space, allowing for better plant arrangement and movement within the greenhouse.

- Even Heat Distribution: Positioned above, they provide uniform heating across the entire area.

- Aesthetic Integration: Often designed to blend seamlessly with the greenhouse structure, maintaining a clean and organized appearance.

Disadvantages

- Installation Complexity: Requires secure mounting and proper alignment to ensure effective heat distribution.

- Higher Initial Cost: Ceiling installations can be more expensive due to mounting hardware and professional installation requirements.

2. Wall-Mounted Infrared Heaters

Overview

Wall-mounted infrared heaters are affixed to the greenhouse walls, providing targeted heating to specific sections or plant beds. They are versatile and can be integrated into existing structures without occupying valuable floor space.

Advantages

- Targeted Heating: Ideal for heating specific areas or plant beds, enhancing growth efficiency.

- Flexibility: Can be easily repositioned or added as needed to accommodate changing heating requirements.

- Ease of Installation: Generally simpler to install compared to ceiling-mounted systems, requiring less structural modification.

Disadvantages

- Limited Coverage: May not provide sufficient heat for larger areas unless multiple units are installed.

- Potential Obstruction: Placement near plants or equipment may require careful positioning to avoid interference.

3. Floor Infrared Heaters

Overview

Floor-mounted infrared heaters are designed to be installed within the greenhouse flooring, often as part of a warm floor system. They provide consistent and gentle heat from the ground up, promoting healthy root development and overall plant growth.

Advantages

- Consistent Heating: Ensures even temperature distribution from the ground level, supporting robust plant growth.

- Energy Efficiency: Minimizes heat loss, as heat is generated close to the plant roots where it is most needed.

- Hidden Installation: Typically concealed within the flooring, maintaining the aesthetic integrity of the greenhouse.

Disadvantages

- Installation Complexity: Requires integration with the greenhouse flooring system, which can be labor-intensive and costly.

- Maintenance Challenges: Accessing heaters for maintenance or repairs may be difficult once installed.

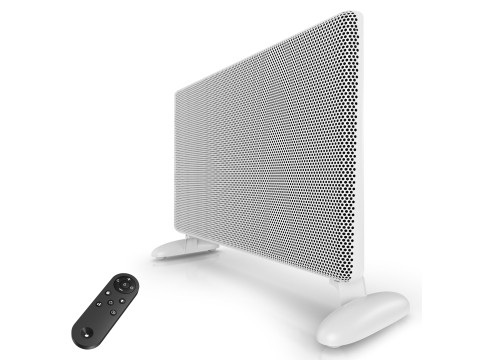

4. Flexible and Decorative Infrared Heaters

Overview

These infrared heaters are designed with aesthetic appeal in mind, featuring decorative panels, flexible films, or moldings that can be integrated into greenhouse interiors. They provide both functional heating and visual enhancement.

Advantages

- Aesthetic Appeal: Enhances the visual appearance of the greenhouse, blending seamlessly with plant arrangements and structures.

- Versatility: Available in various designs and finishes to match different greenhouse styles and decor.

- Space Efficiency: Designed to occupy minimal space, allowing for flexible placement without hindering plant growth.

Disadvantages

- Higher Cost: Decorative and flexible designs may come at a premium compared to standard infrared heaters.

- Specialized Installation: May require specific mounting techniques or professional installation to achieve the desired aesthetic and functional outcomes.

Safety Measures for Infrared Electric Heaters in Greenhouses

Ensuring the safety of infrared electric heaters is paramount to prevent accidents and maintain a healthy growing environment. Implementing proper safety measures helps mitigate risks associated with electrical heating equipment.

1. Waterproof and Weather-Resistant Equipment

Greenhouses are exposed to high humidity and occasional water exposure. It is essential to use infrared heaters that are waterproof or weather-resistant to prevent electrical hazards.

- IP Ratings: Choose heaters with appropriate Ingress Protection (IP) ratings. For greenhouses, an IP rating of at least IP44 is recommended to protect against water splashes from any direction.

- Encased Components: Ensure that all electrical components are properly encased to prevent moisture ingress.

2. Ground Fault Circuit Interrupters (GFCI)

Installing Ground Fault Circuit Interrupters (GFCI) in the greenhouse electrical system provides an additional layer of protection against electrical shocks.

- Automatic Shutdown: GFCIs automatically shut off power if they detect a ground fault, preventing potential electrical accidents.

- Installation: Ensure that GFCIs are installed by a licensed electrician to comply with electrical safety standards.

3. Proper Installation and Maintenance

Correct installation and regular maintenance of infrared heaters are crucial for safe operation.

- Professional Installation: Engage licensed electricians to install infrared heaters, ensuring compliance with local electrical codes and standards.

- Regular Inspections: Periodically inspect heaters for signs of wear, damage, or malfunction. Replace or repair damaged units promptly to maintain safety.

- Clear Placement: Position heaters away from flammable materials, plant beds, and water sources to reduce the risk of fires and electrical hazards.

4. Use of Timers and Thermostats

Implementing timers and thermostats helps regulate heater operation, preventing overheating and reducing energy consumption.

- Automated Controls: Use programmable thermostats to maintain optimal temperatures without manual intervention.

- Timers: Set heaters to operate only during specific hours, reducing the risk of prolonged heating and potential accidents.

5. Adequate Ventilation

Maintaining adequate ventilation ensures that the greenhouse environment remains healthy for plant growth and prevents the buildup of excess heat.

- Air Circulation: Use fans and ventilation systems to promote air movement, preventing hotspots and ensuring even temperature distribution.

- Avoid Overheating: Proper ventilation helps prevent overheating, which can stress plants and reduce their growth efficiency.

6. Electrical Safety Practices

Adhering to electrical safety practices is essential to prevent accidents and ensure the longevity of heating equipment.

- Proper Wiring: Ensure that all electrical connections are secure and free from damage.

- Surge Protection: Use surge protectors to safeguard heaters against voltage spikes and electrical surges.

- Avoid Overloading Circuits: Distribute heaters across multiple circuits to prevent overloading and reduce the risk of electrical fires.

Advantages and Disadvantages of Infrared Electric Heaters for Greenhouses and Nurseries

Advantages

Comfort and Efficiency:

- Direct Heat Transfer: Over 90-95% of the heat energy is absorbed directly by plants and objects, enhancing growth efficiency.

- High Energy Efficiency: Minimizes energy waste by targeting specific areas, leading to significant energy savings.

- Rapid Heating: Provides immediate warmth, reducing the time needed to achieve desired temperatures.

Safety and Aesthetics:

- No Open Flames: Eliminates risks associated with gas leaks and fire hazards, ensuring a safer growing environment.

- Compact and Aesthetic Designs: Available in various sizes and styles that blend seamlessly with greenhouse interiors without occupying valuable space.

- Low Maintenance: Requires minimal upkeep compared to other heating systems, reducing the burden on greenhouse owners.

Ease of Installation:

- Flexible Placement: Can be mounted on ceilings, walls, or floors, allowing for versatile installation based on greenhouse layout.

- Plug-and-Play Operation: Most infrared electric heaters are easy to install and operate without the need for complex setups.

Precise Control:

- Thermostats and Programmers: Enable accurate temperature settings and scheduling to optimize comfort and energy use.

- Smart Integration: Compatible with smart home or greenhouse management systems for remote monitoring and control, allowing for automated and efficient heating management.

Disadvantages

Higher Energy Costs:

- Electricity Dependence: Operating costs can be high, especially in regions with elevated electricity rates, making them less economical for prolonged use.

- Operational Expenses: Continuous use without proper temperature control can lead to significant energy consumption and higher utility bills.

Installation Limitations:

- Electrical Load Requirements: Requires adequate electrical capacity, which may necessitate upgrades to the greenhouse’s electrical system, especially for high-capacity heaters.

- Placement Constraints: Not suitable for all greenhouse layouts, particularly those with limited mounting options or incompatible structures.

Maintenance and Longevity:

- Potential for Damage: Heating elements can be damaged by exposure to moisture, heavy equipment placement, or accidental impacts, reducing the heater's lifespan.

- Limited Lifespan: Over time, heating elements may degrade, reducing efficiency and necessitating replacement, which can add to maintenance costs.

Temperature Control Challenges:

- Manual Adjustments: Basic models without advanced controls may require manual adjustments, leading to inconsistent heating and discomfort for plants.

- Thermostat Placement: Improper thermostat placement can result in inaccurate temperature readings and inefficient heating, undermining the heater's effectiveness.

Initial Costs:

- Higher Purchase Price: Infrared electric heaters, especially advanced models with smart features, can be more expensive upfront compared to traditional heating systems.

- Installation Costs: Professional installation may be required for optimal performance and safety, adding to the overall cost.

Choosing the Right Infrared Electric Heater for Your Greenhouse or Nursery

Selecting the appropriate infrared electric heater for your greenhouse or nursery involves evaluating several key factors to ensure it meets your specific heating needs while maintaining energy efficiency and cost-effectiveness.

1. Power and Capacity

Heating Load Calculation: Determine the required heating capacity based on the size of the greenhouse, types of plants, and local climate conditions. A general guideline is 1 kW per 10 m², adjusted for specific needs.

Voltage Requirements: Choose between single-phase (220V) or three-phase (380V) heaters based on the electrical infrastructure and heating demand. Single-phase heaters are suitable for smaller, supplementary heating needs, while three-phase heaters are necessary for larger, primary heating systems.

2. Type of Infrared Heater

- Ceiling Infrared Heaters: Ideal for large-scale greenhouses where floor space is limited, providing uniform heating from above.

- Wall-Mounted Infrared Heaters: Suitable for targeted heating of specific areas or plant beds, offering flexibility in placement.

- Floor Infrared Heaters: Best for consistent heating from the ground up, promoting healthy root development and overall plant growth.

- Flexible and Decorative Infrared Heaters: Perfect for aesthetic integration and versatile heating solutions, enhancing the visual appeal of the greenhouse.

3. Installation Considerations

Electrical Infrastructure: Ensure your greenhouse’s electrical system can support the heater's power requirements, potentially requiring electrical panel upgrades for high-capacity heaters.

Space Availability: Consider the heater's size and weight to ensure appropriate placement within your greenhouse without causing clutter or requiring significant structural support.

Compliance with Codes: Verify that the heater complies with local building and electrical codes to ensure safe and legal installation, especially in commercial greenhouses.

4. Energy Efficiency

Thermostatic Controls: Opt for heaters with precise thermostatic controls to optimize energy usage and maintain desired temperatures efficiently.

Smart Integration: Consider heaters compatible with smart greenhouse management systems for remote monitoring and control, allowing automated adjustments based on occupancy and external conditions.

5. Brand Reputation and Warranty

Manufacturer Reliability: Choose heaters from reputable brands known for quality, durability, and excellent customer support to ensure long-term performance and reliability.

Warranty Terms: Select models with comprehensive warranties to protect against defects and ensure long-term support, providing peace of mind and safeguarding your investment.

6. Additional Features

Safety Mechanisms: Ensure the heater includes essential safety features such as overheat protection, tip-over switches, and thermal cut-offs to prevent accidents and ensure safe operation.

User-Friendly Controls: Look for intuitive controls and easy-to-read displays for convenient operation and monitoring, making it simple to adjust settings as needed.

Maintenance Indicators: Features like self-diagnostic systems or maintenance alerts can simplify upkeep and prevent issues, ensuring the heater remains in optimal condition.

7. Installation and Maintenance Costs

Initial Investment vs. Long-Term Savings: Balance the higher initial cost of certain heaters against potential long-term energy savings and reduced maintenance costs, evaluating the overall cost-effectiveness based on your usage patterns.

Availability of Spare Parts: Ensure that spare parts and replacement components are readily available to facilitate easy maintenance and repairs, minimizing downtime and ensuring continuous heating performance.

Best Practices for Implementing Infrared Electric Heaters in Greenhouses and Nurseries

Implementing infrared electric heaters effectively in your greenhouse or nursery involves strategic planning, careful selection of components, and ongoing management to ensure optimal performance and energy efficiency.

1. Strategic Placement and Zoning

High-Impact Areas: Focus heating in areas where plants require the most warmth, such as near beds, benches, and equipment storage areas, to maximize efficiency.

Zoning: Divide the greenhouse into different heating zones to control temperature independently, enhancing energy efficiency and reducing overall heating costs by only heating occupied areas.

2. Optimize Control Settings

Thermostat Configuration: Properly set thermostats to avoid overheating, reducing energy consumption and maintaining a comfortable growing environment.

Smart Controls: Utilize smart thermostats and remote controls to manage heating schedules, monitor energy usage, and adjust settings based on occupancy and preferences, allowing for automated and efficient heating management.

3. Enhance Greenhouse Insulation

Floor Insulation: Install high-quality insulation beneath heating elements to minimize heat loss downward, increasing system efficiency and ensuring that more heat remains within the greenhouse.

Wall and Roof Insulation: Improve overall greenhouse insulation by using double-glazed panels, thermal curtains, and insulating materials to retain heat more effectively and reduce the heating load on the infrared heater.

4. Choose Compatible Flooring Materials

High Thermal Conductivity: Opt for flooring materials with high thermal conductivity, such as concrete or stone, to ensure effective heat transfer and maximize heating efficiency.

Thickness Considerations: Choose thinner flooring materials or ensure adequate spacing between heating elements and the floor surface to maximize heating efficiency and prevent heat loss.

5. Regular Maintenance and Inspection

Routine Checks: Periodically inspect the heating system for any signs of wear, damage, or malfunction to address issues proactively and maintain optimal performance.

Cleaning: Keep heating elements and vents clean to ensure optimal performance and prevent energy wastage, especially in dusty or humid greenhouse environments.

6. Professional Installation and Compliance

Licensed Professionals: Engage licensed electricians and heating specialists to ensure proper installation, adherence to safety standards, and compliance with local building codes, guaranteeing safe and efficient operation.

Manufacturer Guidelines: Follow the manufacturer’s installation instructions meticulously to maintain warranty coverage and ensure optimal system performance, preventing potential issues and maximizing heater lifespan.

7. Energy-Efficient Practices

Low-Flow Fixtures: Install low-flow watering systems to reduce water consumption without sacrificing plant health, contributing to overall energy savings.

Renewable Integration: Pair infrared electric heaters with renewable energy sources, such as solar panels, to offset electricity usage and enhance sustainability, reducing operational costs and environmental impact.

8. User Education and Training

Operating Instructions: Educate greenhouse staff or household members on how to use and manage the heating system effectively, including setting thermostats and understanding control features, ensuring proper usage and maximizing efficiency.

Safety Practices: Ensure that users are aware of safety precautions, such as maintaining proper clearance around heaters and avoiding placing heavy objects directly on heating elements to prevent damage and ensure safe operation.

Conclusion

Infrared electric heaters provide a versatile and efficient heating solution for greenhouses and nurseries. With their high energy efficiency, ease of installation, and ability to offer targeted warmth, they enhance the growing environment by creating optimal conditions for plant cultivation. While infrared heaters come with certain challenges, such as higher energy costs and installation limitations, their numerous benefits make them a valuable addition to modern greenhouse heating systems.

By understanding the different types of infrared electric heaters, evaluating your greenhouse’s specific needs, and implementing energy-efficient practices, you can achieve a reliable and cost-effective heating solution. Proper installation and regular maintenance are essential to maximize the benefits and ensure the longevity of your infrared heating system.

Key Takeaways:

Understand Heating Types: Familiarize yourself with ceiling-mounted, wall-mounted, floor infrared heaters, and decorative options to choose the right fit for your greenhouse or nursery.

Assess Heating Needs: Evaluate heating demand, greenhouse size, plant types, and local climate conditions to determine the appropriate capacity and type of heater.

Prioritize Energy Efficiency: Implement strategies like proper thermostat settings, zoning, and enhancing greenhouse insulation to maximize energy efficiency.

Choose Compatible Flooring: Select flooring materials with high thermal conductivity to ensure effective heat transfer and optimal system performance.

Regular Maintenance: Keep your heating system well-maintained through regular inspections and proactive repairs to ensure optimal performance and longevity.

Leverage Smart Technology: Utilize smart thermostats and remote controls for enhanced management, automation, and energy savings.

Seek Professional Assistance: Engage licensed electricians and heating specialists for installation and maintenance to ensure compliance with safety standards and optimal system functionality.

Balance Costs and Benefits: Weigh the higher initial investment against the long-term energy savings and comfort benefits of infrared electric heaters.

Integrate Renewable Energy: Explore integrating renewable energy sources like solar panels to offset operational costs and promote sustainability.

Stay Informed: Keep up with advancements in heating technologies to continuously improve and upgrade your system for better performance and efficiency.

For expert assistance in selecting and installing infrared electric heaters for greenhouses and nurseries, ensuring compatibility with your greenhouse’s infrastructure, or accessing comprehensive project documentation, visit safsale.com. Our specialists are ready to help you create a reliable, efficient, and comfortable growing environment tailored to your specific needs.

Important Notice on Standards

All referenced documents and standards in this guide are provided for informational purposes only and should not be used as official publications. For authoritative guidelines and legal requirements, always consult the official standards organizations or regulatory bodies.