Reed Relay: Key Features and Operation

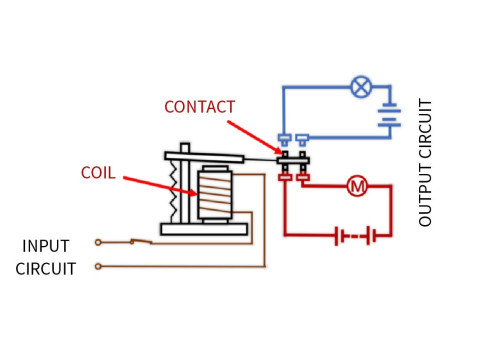

A reed relay is a commutation device primarily used in automation and control circuits. Like traditional electromechanical relays, reed relays contain electrically operated contacts. However, the contacts (known as reed switches) are sealed inside a glass capsule. When exposed to a magnetic field, these thin metal reeds move relative to each other, closing or opening an electrical circuit.

1. How a Reed Relay Works

A typical reed relay consists of:

- K (Reed Switch): The sealed contact(s) inside a glass tube.

- L (Coil): The winding, which creates a magnetic field when current flows through it.

- M (Magnetic Field): Generated by the coil’s current, influencing the reed switch.

Note: The optimal design places the coil around the reed switch or uses a core to ensure the switch sits in the strongest part of the magnetic field. This compact, efficient layout ensures reliable operation.

2. Advantages of Reed Relays

Hermetically Sealed Contacts

- No sparking caused by dust, humidity, or other contaminants.

- Significantly longer service life because the contacts operate in a controlled environment.

Fast Switching

- Low mechanical inertia allows for switching times around 1 millisecond, making reed relays suitable for high-speed circuits.

Low Power Consumption

- Typical current draw is only 5-10 mA, making them ideal for battery-powered or energy-sensitive applications.

Reed Relay Specifications

2.1 Switching Voltage and Current

Most reed relays are rated for relatively low voltages and currents, typically up to around 200 V and 1 A. This makes them best suited for light-duty loads in automation and control circuits. While some specialized designs can handle higher power, their cost can be significantly higher.

2.2 Coil Voltage and Current

- Generally driven by DC power (though some variants also support AC).

- Low coil voltages (commonly from 5 V to 24 V).

- Coil current specifications are sometimes omitted from datasheets, but you can calculate it with Ohm’s Law if coil resistance and operating voltage are provided:

Important: Always refer to the manufacturer’s datasheet for the exact pull-in (operate) and drop-out (release) voltages, which can differ significantly.

2.3 Contact Configuration

Reed relays may offer several contact arrangements:

- Normally Closed (NC) - Contacts remain closed without coil voltage.

- Normally Open (NO) - Contacts remain open in the de-energized state.

- Changeover / SPDT - A combination that can switch between NO and NC contacts.

2.4 Package and Mounting

- Designed predominantly for PCB (printed circuit board) mounting.

- Vary in shape, pin layout, and encapsulation style.

- Enclosures can differ to suit different form factors or environmental requirements.

Conclusion

A reed relay provides reliable, high-speed switching in low-voltage, low-current circuits, making it perfect for automation and control applications. Its hermetic sealing, fast response, and low power usage extend its service life and ensure stable performance. For more detailed information-such as precise voltage, current, and environmental tolerances-always check the datasheet of a specific reed relay model.