Grounding System: Proper Setup and Safety Guidelines

What Is a Grounding System?

A grounding system is a network of conductive components that electrically connect devices and equipment to the earth.

It consists of metal conductors buried in the ground, providing a safe path for electrical currents in case of faults or surges.

The primary function of grounding is to:

- Protect people from electric shocks,

- Prevent damage to electrical appliances and systems,

- Reduce fire risks caused by electrical malfunctions.

For modern homes, grounding is not optional-it is an essential part of the electrical infrastructure. It ensures that any voltage leaks or faults do not create hazardous conditions.

Why Is Proper Grounding Important?

Without an effective grounding system, the risks of electrical hazards increase significantly. Studies show that a large number of electrical accidents in private homes occur due to missing or faulty grounding systems.

A correctly installed grounding system prevents dangerous voltage buildup on exposed metal parts of appliances. This is crucial for avoiding electric shocks and minimizing fire hazards caused by electrical failures.

Main Components of a Grounding System

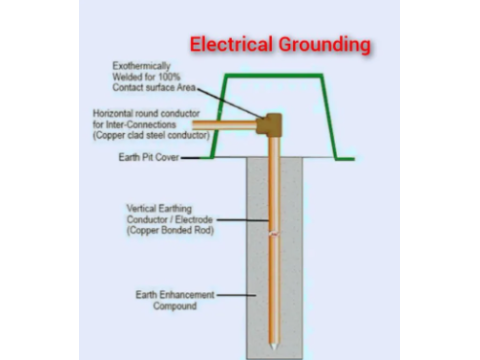

A grounding system consists of several key components:

Grounding Electrodes

These are the conductive elements that make direct contact with the soil. They can be:

- Vertical rods (driven deep into the ground),

- Horizontal strips (laid in trenches).

Grounding Conductors

These connect the electrodes to the main grounding busbar, ensuring a low-resistance path to the earth.

Main Grounding Busbar (MGB)

This is the central connection point where all grounding conductors converge. It links electrical systems and potential equalization conductors to the grounding network.

Material Selection for Grounding

To ensure durability and efficiency, materials used for grounding must be:

- Highly corrosion-resistant,

- Good conductors of electricity.

Common materials include:

- Galvanized steel,

- Copper,

- Copper alloys.

The choice of material depends on soil conductivity and environmental conditions.

Additionally, some grounding systems integrate lightning protection elements, especially in areas prone to frequent storms.

How to Install a Grounding System

Step 1: Planning the Grounding System

Before installation, it’s crucial to assess the soil conditions, as they affect grounding efficiency.

Determine soil resistivity:

- Clay soils provide better conductivity and require fewer electrodes than sandy soils.

Account for seasonal changes:

- In colder climates, electrodes should be placed below the frost line to ensure year-round functionality.

Plan electrode placement:

- Avoid placing electrodes near underground pipes, gas lines, or other metal structures that may interfere with grounding performance.

Step 2: Installing Grounding Electrodes

- Mark the locations for the grounding electrodes.

- Drive vertical electrodes into the ground at least 8-10 feet deep.

- Ensure spacing of at least 10 feet between electrodes to prevent interference.

- Connect the electrodes using horizontal conductors to form a grounding loop.

Step 3: Securing Connections

- All connections must be corrosion-resistant and mechanically secure.

- Protect joints with anti-corrosion coatings to ensure long-term stability.

- Welded connections should be cleaned and coated for durability.

Measuring Ground Resistance

Why Resistance Testing Is Essential

Before activating the system, it’s necessary to measure the grounding resistance to ensure it meets safety standards.

How to Measure Ground Resistance

A ground resistance tester (also called an earth resistance meter) is used for testing. The three-electrode method is the most common technique.

- Electrodes are placed at a specific distance from the grounding system to provide accurate readings.

- Testing should be performed in dry weather conditions to obtain stable results.

Acceptable Resistance Levels

- For residential homes with a TN-C-S system, the resistance should not exceed 30 ohms.

- If a GFCI (Ground Fault Circuit Interrupter) is used, slightly higher resistance values may still ensure safety.

Maintenance and Inspection of the Grounding System

To maintain long-term reliability, grounding systems require periodic inspections and testing.

Inspection Frequency:

- Visual inspections should be performed at least once a year to check for corrosion or damage.

- Resistance measurements should be taken every three years to ensure effectiveness.

Common Issues and Fixes:

- If resistance increases over time, additional grounding electrodes may be needed.

- Loose or corroded connections must be repaired immediately to prevent failure.

Record-Keeping:

- All inspection reports and maintenance logs should be documented to track system performance.

Common Grounding Mistakes to Avoid

1. Installing Electrodes Too Shallow

- If electrodes are above the frost line, they may lose conductivity in winter.

- Solution: Install electrodes below the freezing depth for stability.

2. Using Inadequate Materials

- Poor-quality metal corrodes quickly, reducing grounding effectiveness.

- Solution: Use galvanized steel or copper, which provide better longevity.

3. Improper Placement of Grounding Electrodes

- Electrodes placed too close together interfere with each other, reducing system efficiency.

- Solution: Maintain at least 10 feet between electrodes for proper grounding distribution.

Final Thoughts

A properly installed grounding system is essential for home electrical safety. It prevents electric shocks, protects appliances, and reduces fire hazards.

Key Takeaways:

- Plan the installation carefully, considering soil conditions and seasonal changes.

- Use corrosion-resistant materials to ensure long-term effectiveness.

- Test grounding resistance regularly and maintain proper documentation.

- Never skip routine maintenance-a well-maintained grounding system lasts for decades.

If you’re unsure about installation or measurements, consult a licensed electrician to ensure compliance with National Electrical Code (NEC) standards.

Investing in quality grounding and regular maintenance is an investment in home safety and electrical reliability.