Grounding in a Private House: Installation and Safety Standards

Why Is Grounding Important?

Grounding is a critical safety measure that minimizes touch voltage risks and protects electrical systems from faults.

Many homeowners recognize the importance of having a proper grounding system on their property. However, grounding is not a standalone feature—it is part of the entire power distribution network and must align with the characteristics of the electrical system in place.

Before installing a grounding system, you need to determine what type of grounding scheme is used in your home's electrical supply.

Types of Grounding Systems

Different electrical grounding systems dictate how grounding should be implemented in a private house. Let’s go over the main systems:

1. TN-S System

If your house receives power via a three-phase five-wire or single-phase three-wire connection with separate N (neutral) and PE (protective earth) conductors, there is no mandatory requirement to install additional grounding on your property.

- The National Electrical Code (NEC) recommends additional grounding (bonding) at the house entrance but does not require it.

- The grounding busbar inside the house should be connected to the PE conductor.

- The total ground resistance of all electrodes in the power distribution line should not exceed 10 ohms, while individual electrodes should not exceed 30 ohms.

2. TN-C System

This older and still common system does not provide a separate PE conductor. Instead, the PEN conductor (combined neutral and ground) is used.

- In this case, additional grounding (PEN bonding) is mandatory at the house entrance.

- If you install a Ground Fault Circuit Interrupter (GFCI, or RCD in Europe), you must install a dedicated grounding electrode at the entrance.

3. TN-C-S System

To enhance safety, the TN-C system can be converted into TN-C-S by separating the PEN conductor into N and PE conductors.

- In this case, a grounding electrode must be installed at the point of separation.

- Once separated, the grounding requirements are the same as the TN-S system.

4. TT System

This system requires independent grounding electrodes for each consumer.

- Grounding resistance must not exceed 4 ohms for 0.4 kV power lines.

- GFCI installation is mandatory in the TT system.

- The grounding electrodes must undergo regular inspections, and resistance measurements must be conducted by licensed specialists.

In cases where the main power line is in poor technical condition, transitioning to a TT grounding system may be the only safe option.

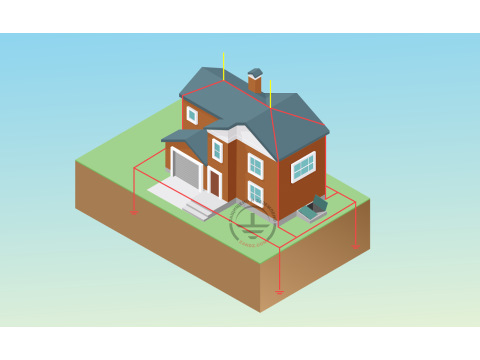

Grounding Electrode Design and Installation

Types of Grounding Electrodes

Grounding systems can use either natural or artificial electrodes.

Natural Grounding Electrodes

These include:

- Steel reinforcements in concrete foundations,

- Metal support structures,

- Buried underground pipelines (except for gas or fuel lines).

While some buried structures naturally provide grounding, modern regulations discourage using water pipes, heating systems, or gas lines as grounding conductors due to safety risks.

Artificial Grounding Electrodes

These are specially installed conductive elements designed for grounding purposes.

- The most common grounding electrodes include steel rods, copper-clad rods, and galvanized steel strips.

- The grounding system should also be bonded to metal structures within the house, such as pipes and construction elements, to create a potential equalization network.

Recommended Grounding Electrode Design

The design of the grounding system is not strictly regulated but typically follows a triangular layout:

- Three vertical electrodes are installed at the corners of an equilateral triangle (1–2 meters per side).

- The rods are driven 8–10 feet deep into the ground.

- The electrodes are connected with horizontal conductors to form a closed loop.

This system ensures efficient current dissipation into the ground and improves grounding performance.

Materials for Grounding Electrodes

- Galvanized steel is commonly used due to its cost-effectiveness and durability.

- Copper-clad rods provide lower resistance and higher longevity but are more expensive.

- Aluminum is not used, as it corrodes rapidly underground.

Bonding to the House’s Electrical System

- The grounding electrodes should be connected to a grounding busbar inside the home.

- All major appliances (washing machines, ovens, heating systems, etc.) should be grounded using three-prong outlets.

- The grounding system should be bonded to metal pipes to prevent electric potential differences within the house.

Testing and Maintenance of a Grounding System

Ground Resistance Testing

- Ground resistance should be measured upon installation and every 3 years.

- A ground resistance tester (earth resistance meter) is used to ensure the system meets regulatory standards.

Testing Methodology

The most common method is the three-electrode test, where resistance is measured using test rods placed at specific distances.

Regulatory Limits:

- For residential homes (TN-C-S, TN-S systems): ≤ 30 ohms.

- For TT systems: ≤ 4 ohms.

Regular Inspections

- Visual checks should be done annually to look for corrosion, mechanical damage, or loose connections.

- Resistance measurements should be taken at least every three years.

Common Mistakes to Avoid in Grounding Installation

1. Installing Electrodes Too Shallow

- Electrodes must be deep enough to reach stable soil moisture levels.

- In colder climates, they must be below the frost line to remain effective year-round.

2. Using Inadequate Materials

- Low-quality metals corrode quickly and compromise grounding effectiveness.

- Always use galvanized steel or copper-clad electrodes for long-term performance.

3. Incorrect Placement of Grounding Electrodes

- Electrodes should be spaced at least 10 feet apart to prevent mutual interference.

Conclusion

A properly installed grounding system is crucial for home electrical safety. It:

✅ Prevents electric shock hazards

✅ Protects electrical appliances from power surges

✅ Reduces the risk of electrical fires

Key Takeaways:

- Assess the existing grounding system before installing new grounding.

- Use high-quality materials to prevent corrosion and ensure longevity.

- Test grounding resistance regularly to comply with safety standards.

- Follow proper installation guidelines and consult a licensed electrician when in doubt.

Investing in a well-designed and properly maintained grounding system is an investment in home safety and electrical reliability.