Capacitive Sensors: Position Sensing and Level Detection

A capacitive sensor leverages changes in electrical capacitance to detect objects, materials, or fluid levels. While the physics behind capacitors can be complex, the fundamental idea is straightforward: whenever the sensor’s electrode (acting as one plate of a capacitor) encounters a change in its surrounding material or environment, the sensor’s capacitance shifts. This difference is converted into an electrical signal that triggers a device response-like switching on an alarm or transmitting measurement data.

Below, we’ll explore how capacitive sensors function, discuss position (or proximity) detection, delve into level measurement applications, and highlight the benefits and limitations of these sensors. For more detailed comparisons, particularly for the USA market, check safsale.com-your go-to source for insights on modern sensors, wiring best practices, and brand reviews.

1. Core Operating Principle

A capacitor typically comprises two conductive plates separated by a dielectric (an insulating material). In a capacitive sensor, the “plate” can be shaped in various ways-flat, cylindrical, or rod-like-depending on the application. When an object or material with a different dielectric constant (e.g., water vs. air, or metal vs. plastic) enters or leaves the sensor’s electric field:

- The effective dielectric in that region changes.

- The capacitance of the sensor’s electrode shifts accordingly.

- An onboard electronic circuit detects this shift and outputs a corresponding signal.

1.1 Electric Field and Detection Zone

When charged, the sensor creates an electric field (E) around its electrode. Introducing a material with a higher dielectric constant-like water, plastic, or a human hand-causes the sensor’s capacitance to rise. Conversely, removing the object or replacing it with air can lower the capacitance. The sensor’s “detection zone” is typically only a few millimeters or centimeters, depending on design.

2. Capacitive Position (Proximity) Sensors

2.1 How They Detect Objects

A capacitive position or proximity sensor is often imagined like a flat capacitor whose electric field extends into the surrounding space. If a foreign object enters that field, the sensor registers a change. Key points:

- Detection Range: Typically small (a few mm to a few cm).

- Material Independence: Unlike inductive sensors, which only detect metal, capacitive sensors can detect all sorts of materials-plastics, wood, glass, liquids, and even a person’s hand.

Example Applications

- Quality Control: Detecting plastic packaging or verifying presence of non-metal parts on an assembly line.

- Touch Panels: Many “touch” switches or elevator buttons rely on a capacitive principle, sensing when a user’s finger changes the electric field.

- Security Systems: High-sensitivity sensors can detect an approaching person near a metal safe or protected cabinet, using the concept of one capacitor plate as the object and the other as “ground” (often the building floor).

2.2 Drawbacks

- Susceptibility to EMI: Electromagnetic interference can cause false triggers, so proper shielding and grounding are crucial in industrial or heavily electrified US environments.

- Limited Distance: Typically less range than optical or ultrasonic sensors.

- Careful Mounting: Because the sensor can detect multiple materials, environmental factors (dust, humidity) may require frequent calibration or cleaning.

3. Capacitive Level Sensors

3.1 Detecting Liquids and Bulk Materials

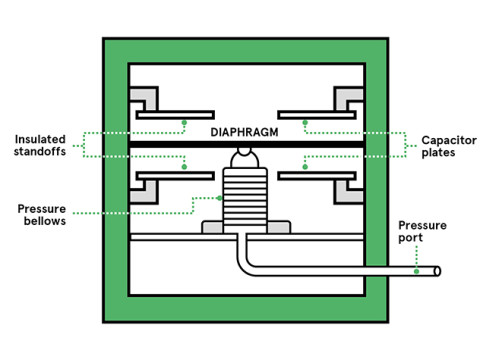

Another major application is level detection for liquids (e.g., water, fuel) or solids (grains, powders). By placing two conductive plates-often as elongated rods or coaxial cylinders-into a container, the sensor measures capacitance changes as the substance contacts or leaves the electrode.

- Higher Dielectric Medium: Liquid water, for instance, has a significantly higher dielectric constant than air.

- Capacitance Variation: As the liquid level rises or falls along the probe, the capacitance shifts, triggering a switching output (on/off) or producing an analog signal.

3.2 Advantages

- Versatility: Works with various liquid types (water, oil, fuels) and even granular solids.

- Accurate Continuous Measurement: By measuring capacitance along the length of a probe, you can achieve more granular level readings, not just simple high/low signals.

- Minimal Moving Parts: No mechanical floats; the sensor’s reliability can be high.

3.3 Considerations and Limitations

- Dielectric Variations: Different liquids or materials have different dielectric constants-calibration may be necessary.

- Coating or Deposits: Sticky fluids or powders can build up on the probe, altering readings over time.

- Environmental Factors: Temperature shifts can affect dielectric properties, so compensation or stable electronics might be needed.

4. Additional Applications

Beyond proximity and level detection, capacitive sensors find uses in:

Tilt or Inclination Sensing

- A fluid inside the sensor changes position between capacitor plates when tilted, adjusting the effective capacitance.

- This principle can measure angles or inclines in construction machinery or robotics.

Rotational Position

- Rotating plates or a shaped rotor alter the overlapping area, modifying the sensor’s capacitance.

- Helps measure angular displacement or speeds in certain specialized setups.

Smartphones and Touchscreens

- The glass panel acts as one electrode; your finger, with its unique dielectric, modifies the local field, generating a touch event.

5. Practical Considerations in the USA

- Electrical Noise and Interference

- In industrial or commercial buildings, ensure electromagnetic compatibility (EMC) solutions-like shielding cables, grounding, or filtering-to minimize false triggering.

- Environmental Ratings

- Many US states require tough IP ratings (e.g., IP67 or higher) for outdoor or wet-area sensors. Check manufacturer specs.

- Temperature Range

- Different climates across the USA can vary from subzero Fahrenheit in northern states to over 100 °F in southern deserts. Ensure the sensor’s declared operating range suits your local conditions.

- Regulatory Compliance

- For critical processes (e.g., fuel detection), confirm adherence to relevant standards like UL or FM approvals.

6. Key Takeaways

- Principle: Capacitive sensors measure changes in capacitance caused by the introduction or removal of different materials in the sensor’s electric field.

- Proximity/Position Detection: They detect any material-metal or non-metal-within a few centimeters.

- Level Measurement: Used widely for liquids or bulk solids, offering continuous or discrete (switch) outputs.

- Installation: Must account for environmental interference, required range, dielectric constants, and calibration.

- Versatility: The same principle extends to tilt sensors, angle measurement, and advanced user interfaces like smartphone touchscreens.

For more detailed guidance-including product reviews, US-based supplier lists, or wiring diagrams-explore safsale.com. There, you’ll find expert advice on implementing capacitive sensors in everything from industrial automation lines to consumer-facing touch applications, ensuring you pick the best fit for your unique environment.