What Is Protective Grounding?

Protective grounding is a safety system designed to prevent electric shock and divert fault currents safely into the ground. It ensures that metal components of electrical devices remain at a safe potential, reducing the risk of accidental electrocution.

Why Is Protective Grounding Important?

✔ Prevents electric shock – Ensures that faulty appliances don’t become a hazard.

✔ Redirects fault currents – Guides excess electricity safely into the ground.

✔ Triggers circuit breakers – Cuts power instantly in case of short circuits.

✔ Enhances system reliability – Prevents voltage fluctuations and interference.

Electrical faults such as insulation breakdown or wire damage can lead to hazardous voltages on metal casings of electrical appliances. Without proper grounding, touching these surfaces can be fatal.

How Does Protective Grounding Work?

The grounding system connects exposed metal parts of electrical devices to the earth via a low-resistance conductor. If a fault occurs, the electricity is diverted into the ground, preventing it from passing through a person.

Example:

Imagine a refrigerator’s internal wiring accidentally touches its metal body. If the refrigerator isn’t grounded, anyone touching it could get electrocuted.

With proper grounding, the current flows through the ground wire instead, causing the circuit breaker to shut off power immediately.

Protective Grounding vs. Functional Grounding

Many confuse protective grounding with functional grounding, but they serve different purposes:

| Type | Function | Purpose |

|---|---|---|

| Protective Grounding (PE) | Diverts dangerous fault currents to the ground | Prevents electric shock |

| Functional Grounding (N) | Ensures equipment operation by stabilizing voltage | Keeps electrical systems running smoothly |

Some systems combine both (TN-C, TN-C-S), but modern installations separate them for enhanced safety.

Regulations and Standards for Protective Grounding

Protective grounding must comply with safety codes to ensure reliability. Key requirements include:

✔ Grounding resistance ≤ 30 ohms for standard installations.

✔ Grounding electrodes must be at least 8 feet deep.

✔ All exposed conductive parts must be connected to ground.

✔ Regular testing of grounding resistance to ensure effectiveness.

Note: In high-risk environments (substations, hospitals, and industrial facilities), the maximum resistance is reduced to 4 ohms.

Types of Protective Grounding Systems

1. TN Systems (TN-C, TN-S, TN-C-S)

✔ Most common in homes and businesses

✔ Uses a dedicated grounding wire (PE)

✔ Provides high reliability and safety

2. TT System

✔ Used when separate grounding electrodes are needed

✔ Ensures each installation has independent grounding

✔ Common in rural areas and older buildings

3. IT System

✔ Designed for industrial and medical applications

✔ Minimizes electrical failures by isolating the neutral

✔ Reduces risk of power outages in hospitals and factories

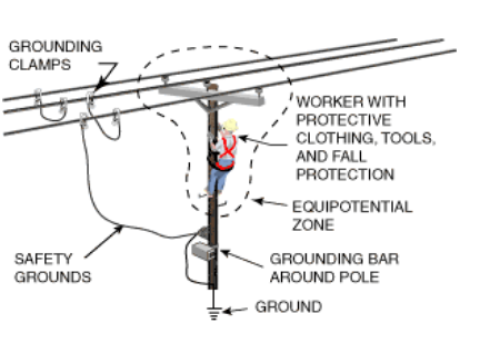

Main Components of a Grounding System

✔ Grounding Electrode (Rod or Plate) – The main component buried in the ground.

✔ Grounding Conductor (PE Wire) – Connects the system to the electrode.

✔ Main Grounding Busbar – Central point where all ground wires connect.

✔ Bonding Jumpers – Ensure all grounded parts are at the same potential.

The better the connection between these elements, the more effective the grounding system will be.

How to Install Protective Grounding

1. Install the Grounding Electrode

✔ Use a copper-clad steel or galvanized steel rod.

✔ Drive the electrode at least 8 feet deep for good soil contact.

2. Connect the Grounding Wire

✔ Use thick copper or aluminum conductors for safety.

✔ Securely fasten the wire to all appliances, panels, and outlets.

3. Bond Metal Structures

✔ Ground metal water pipes, HVAC systems, and structural steel.

✔ Ensures voltage equalization to prevent accidental shocks.

4. Regularly Test the Grounding System

✔ Use a ground tester to check resistance (should be under 30 ohms).

✔ Inspect for corroded wires or loose connections.

Common Grounding Issues and Fixes

High Grounding Resistance

✔ Solution: Install additional grounding rods spaced 6 feet apart.

Loose or Damaged Ground Wires

✔ Solution: Replace corroded wires and secure all connections.

Improper Grounding in Old Homes

✔ Solution: Upgrade wiring to a TN-S or TN-C-S system.

Using Water Pipes as Grounding

⚠ Warning: NEVER use indoor plumbing pipes for grounding. Always install dedicated grounding rods.

Testing and Maintenance of a Grounding System

✔ Annual Resistance Testing – Ensure ground resistance stays within limits.

✔ Check for Loose Connections – Inspect all grounding connections in the electrical panel.

✔ Look for Corrosion – Replace rusted rods and conductors.

✔ Verify Bonding – Ensure all metal components are correctly bonded.

Warning: Improper maintenance can lead to equipment failures and electric shocks. Regular checks are essential for safety.

Key Takeaways on Protective Grounding

✔ Prevents electric shock by safely redirecting fault currents

✔ Protects appliances from power surges and voltage fluctuations

✔ Ensures compliance with electrical safety regulations

✔ Must be tested and maintained regularly for maximum efficiency

For high-quality grounding equipment and safety solutions, visit safsale.com for expert recommendations and installation guides!

Need professional-grade electrical protection? Trust safsale.com for reliable grounding supplies and expert advice!