Electrical Wires and Cables - Types, Selection, and Installation

Choosing the right electrical wire and cable is crucial for safety, efficiency, and compliance with modern electrical codes. The correct selection depends on insulation type, conductor material, cable size, and application. This guide covers the main wire types, selection criteria, and proper installation methods.

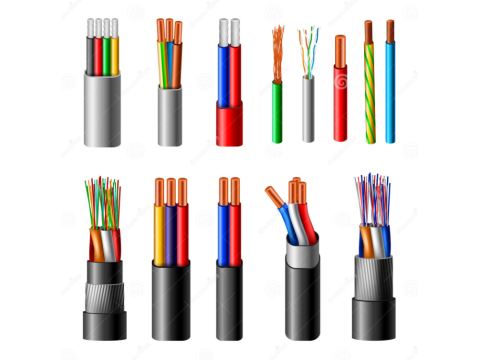

1. What Are Electrical Wires and Cables?

Electrical wiring consists of conductors that transmit electricity throughout a building. The key elements include:

- Conductor Material - Copper or aluminum.

- Insulation - PVC, rubber, or other polymers.

- Cable Type - Single-core or multi-core for different applications.

The right selection ensures minimal energy loss, safe operation, and long-lasting performance.

2. Common Electrical Wire and Cable Types

Electrical conductors come in different types, each suited for specific applications.

2.1 NM (Non-Metallic Sheathed Cable) - "Romex®"

Best for: Residential indoor wiring

Features:

- Copper conductors

- PVC insulation and outer sheath

- Cannot be used in wet locations

2.2 THHN/THWN (Thermoplastic-High-Heat Nylon-Coated Wire)

Best for: Commercial and industrial wiring, conduit installations

Features:

- High heat and moisture resistance

- Commonly used in metal conduits

- Can be used outdoors in conduit

2.3 UF (Underground Feeder) Cable

Best for: Direct burial underground wiring

Features:

- Water-resistant PVC insulation

- Used for outdoor and underground applications

- Withstands moisture, dirt, and exposure

2.4 MC (Metal-Clad) Cable

Best for: Industrial and commercial applications

Features:

- Aluminum or steel protective sheath

- High durability against mechanical damage

- Often used for high-voltage applications

2.5 BX (Armored Cable)

Best for: Exposed wiring in commercial buildings

Features:

- Flexible metal protection

- Reduces fire risk

- Requires metal connectors for termination

2.6 Flexible Cords (Extension and Appliance Cords)

Best for: Temporary wiring, appliances, tools

Features:

- High flexibility

- Insulated with rubber or PVC

- Not for permanent installations

3. How to Choose the Right Electrical Wire and Cable

Selecting the correct wire or cable depends on several factors:

3.1 Voltage and Amperage Rating

The electrical wire must support the voltage and current load required by the circuit.

| Wire Gauge (AWG) | Max Amps (Copper, 75°C) | Common Use |

|---|---|---|

| 14 AWG | 15A | Lighting circuits |

| 12 AWG | 20A | General outlets |

| 10 AWG | 30A | Water heaters, AC units |

| 8 AWG | 40A | Electric stoves |

| 6 AWG | 55A | Large appliances, subpanels |

| 4 AWG | 70A | Main service entrance |

| 2 AWG | 95A | High-powered electrical panels |

3.2 Conductor Material - Copper vs. Aluminum

- Copper - Higher conductivity, more durable, corrosion-resistant.

- Aluminum - Cost-effective for high-power transmission but requires special connectors.

For residential wiring, copper is recommended due to better conductivity and longevity.

3.3 Insulation and Sheathing Material

Wire insulation protects against moisture, heat, and mechanical damage.

| Insulation Type | Best For | Properties |

|---|---|---|

| PVC (Polyvinyl Chloride) | Indoor wiring | Low cost, good flexibility |

| THHN (Thermoplastic, High Heat-Resistant Nylon) | Conduits, commercial buildings | Heat-resistant, moisture-resistant |

| XHHW (Cross-Linked Polyethylene, High Heat & Water-Resistant) | Outdoor, industrial | UV-resistant, withstands extreme temperatures |

| Rubber (EPR, Neoprene) | Temporary cords, appliances | High flexibility, durable in harsh environments |

For outdoor and wet areas, use THWN-2 or XHHW-2 wires to prevent moisture damage.

3.4 Indoor vs. Outdoor Use

- Indoor Wiring: Romex® (NM), THHN in conduit.

- Outdoor & Underground: UF cable, THWN-2 in conduit.

- Heavy-Duty: MC or BX cables for commercial spaces.

Using the wrong cable type can lead to electrical failures, fire hazards, and code violations.

4. Proper Installation Methods

4.1 Wire Routing and Protection

- Wires must follow code-approved pathways through walls, ceilings, and conduits.

- Avoid running cables near heat sources or sharp edges.

- Secure all wires using cable clamps or fasteners at proper intervals.

4.2 Underground Cable Installation

For underground wiring, use UF cables or conduit-protected THWN wires.

- Direct Burial: Bury UF cable at least 24 inches deep.

- Conduit Installation: Use PVC or metal conduit for extra protection.

- Avoid moisture exposure by sealing conduit joints properly.

4.3 Common Mistakes to Avoid

❌ Using undersized wires - Causes overheating and power losses.

❌ Ignoring NEC rules - Can lead to safety hazards and failed inspections.

❌ Mixing copper and aluminum wires - Causes corrosion unless using special connectors.

❌ Using indoor-rated cables outdoors - Leads to insulation breakdown and electrical faults.

5. NEC Compliance and Electrical Code Requirements

The National Electrical Code (NEC) mandates specific wiring standards for safety and performance.

Key NEC Rules:

✔ All wires must be rated for their intended environment.

✔ Outdoor wiring requires UV-resistant insulation.

✔ GFCI protection is required for bathrooms, kitchens, outdoor outlets.

✔ AFCI breakers must be installed in bedrooms and living spaces.

✔ Conduit is required for exposed wiring in commercial areas.

For detailed compliance, check local building codes, as some states have additional regulations beyond NEC guidelines.

6. Conclusion - Choosing the Right Wire for Your Needs

Selecting the right electrical wire ensures safe operation, energy efficiency, and compliance with NEC standards.

- For general home wiring: Use Romex® (NM) for dry locations.

- For wet/outdoor use: Choose UF cable or THWN-2 in conduit.

- For commercial spaces: Consider MC or BX cables.

For high-quality electrical wires, tools, and installation accessories, visit safsale.com.

If unsure about wire selection, NEC codes, or installation, consult a licensed electrician for professional guidance.