Electrical Contacts: Types, Characteristics & Functions

An electrical contact is a conductive interface between materials that allows current to pass through an electrical circuit.

Electrical contacts are found in switches, relays, circuit breakers, connectors, and other electrical devices where current flow needs to be controlled or transmitted efficiently.

This article explores the types, characteristics, and applications of electrical contacts.

🔹 What Is an Electrical Contact?

An electrical contact is the point of connection between two conductors where current passes through.

These connections can be:

✅ Fixed (Permanent) - Such as soldered or welded connections

✅ Movable (Switching/Sliding) - Found in switches, relays, and brushes in motors

Electrical contacts must provide:

✔️ Low resistance - To minimize energy loss

✔️ High conductivity - To allow smooth current flow

✔️ Durability - To withstand wear, heat, and corrosion

Electrical contacts come in various types based on their function, form, and material composition.

1️⃣ Types of Electrical Contacts

Electrical contacts can be categorized into four main types:

✔️ 1. Fixed (Non-Detachable) Contacts

🔹 These permanent connections cannot be separated without breaking the connection.

🔹 They ensure strong and stable current transmission.

Examples:

✅ Soldered joints - Found in circuit boards

✅ Welded connections - Used in power cables

✅ Crimped terminals - Common in automotive wiring

📌 Best for high-reliability circuits where movement is not required.

✔️ 2. Detachable (Removable) Contacts

🔹 Designed for easy disconnection and reconnection.

🔹 Allows flexibility for maintenance, replacement, or modifications.

Subtypes:

✅ Screw & bolt terminals - Used in electrical panels

✅ Plug & socket connectors - Found in household appliances

✅ Spring-loaded clamps - Used in industrial control panels

📌 Common in electrical installations where wiring needs adjustments.

✔️ 3. Sliding Electrical Contacts

🔹 Designed for continuous or rotational movement while maintaining electrical connection.

Examples:

✅ Carbon brushes in electric motors & generators

✅ Sliding contacts in voltage regulators

✅ Rotary switches & slip rings

📌 Used in applications where continuous movement occurs, such as in motors and industrial machines.

✔️ 4. Switching & Control Contacts

🔹 Found in switches, relays, and circuit breakers, used to open or close circuits.

Types of switching contacts:

✅ Normally Open (NO) - Contact remains open until actuated

✅ Normally Closed (NC) - Contact remains closed until actuated

✅ Changeover Contacts (SPDT, DPDT, etc.) - Can switch between two circuits

📌 Essential in control systems for automation and electrical safety.

2️⃣ Key Characteristics of Electrical Contacts

Electrical contacts must have reliable performance under various conditions.

✔️ 1. Electrical Conductivity

🔹 High conductivity reduces power loss.

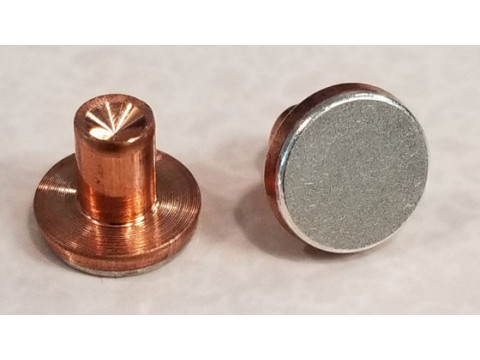

🔹 Common materials: Silver, copper, gold, and alloys.

📌 Gold and silver contacts offer superior conductivity but can be costly.

✔️ 2. Contact Resistance

🔹 Resistance at the contact interface affects performance.

🔹 Lower resistance = More efficient current flow.

📌 Oxidation, contamination, and mechanical wear can increase resistance over time.

✔️ 3. Switching Speed

🔹 Time required for the contact to open or close.

🔹 Important in relays and circuit breakers for fast switching.

📌 Faster switching prevents arcing and improves device longevity.

✔️ 4. Contact Wear & Durability

🔹 Frequent use can cause erosion, pitting, or contamination.

🔹 Wear depends on current levels, switching frequency, and material properties.

📌 Silver alloys and tungsten improve wear resistance in high-power applications.

✔️ 5. Arc Resistance

🔹 Switching contacts may experience electrical arcing, damaging surfaces.

🔹 Arc-resistant materials like tungsten extend contact life.

📌 Found in high-voltage relays and heavy-duty switches.

3️⃣ Applications of Electrical Contacts

Electrical contacts are found in nearly every electrical system, from household wiring to industrial power networks.

✔️ 1. Power & Control Systems

✅ Switches & Circuit Breakers - Control and protect electrical circuits

✅ Relays & Contactors - Used in automation systems and industrial machinery

✅ Rotary Connectors (Slip Rings) - Found in wind turbines and rotating equipment

📌 Used in power grids, substations, and industrial motor controls.

✔️ 2. Consumer Electronics

✅ Plugs & Sockets - Found in household appliances

✅ Battery Contacts - Used in mobile phones and remote controls

✅ Audio & Data Connectors - Found in speakers, headphones, and USB ports

📌 Provides reliable electrical connectivity in everyday devices.

✔️ 3. Automotive & Aerospace

✅ Starter Motor Contacts - Engages during ignition

✅ Sensor & ECU Contacts - Used in vehicle electronics

✅ Aircraft & Satellite Connectors - High-reliability gold-plated contacts

📌 Critical for ensuring uninterrupted power in vehicles and aerospace systems.

4️⃣ Choosing the Right Electrical Contact

When selecting an electrical contact, consider:

✅ Voltage & Current Ratings - Ensure it meets circuit demands

✅ Material Type - Silver for high conductivity, tungsten for durability

✅ Environmental Factors - Resistance to corrosion and temperature variations

✅ Mechanical Wear Resistance - Required for frequently operated contacts

📌 Choosing the right contact ensures reliability, efficiency, and long-term performance.

5️⃣ Conclusion: The Importance of Electrical Contacts

Electrical contacts enable the efficient transmission and control of electrical power in various applications.

✔ Fixed, detachable, sliding, and switching contacts serve different needs.

✔ Material selection impacts performance and longevity.

✔ Proper maintenance and selection enhance reliability in critical systems.

🚀 Advancements in contact materials and coatings are improving performance in modern electrical systems!