Reed Sensor and Its Construction: Types and Uses

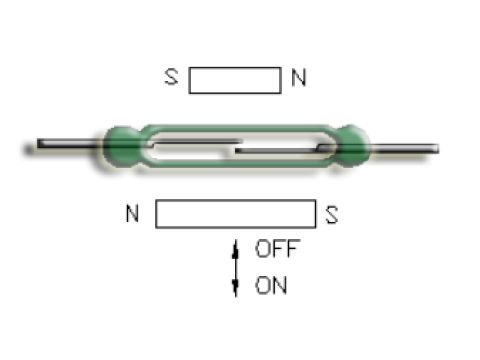

A reed sensor operates on the principle of a reed switch whose contact plates open or close when subjected to a magnetic field. Essentially, the sensor consists of two components housed separately:

- Reed Switch - Sealed in a small, airtight glass tube

- Magnet - Positioned at a certain distance from the switch

When the magnet approaches or recedes, the reed switch is triggered-either closing or opening the internal metal contacts to produce an electrical signal. Below, we’ll cover how these sensors work, typical variants you’ll see in the USA, and common applications. If you need more brand-specific guidance or US code insights, check safsale.com for dedicated resources and product comparisons.

1. How a Reed Sensor Works

1.1 Reed Switch Overview

A reed switch is a small set of contact blades (usually two thin, ferrous metal plates) hermetically sealed in a glass capsule. This design provides:

- Protection from corrosion or airborne contaminants

- No mechanical drive - The switch uses a magnetic force to move the contacts

- Minimal sparking - Safer for potential flammable or explosive environments

When the magnetic field from a nearby magnet is strong enough, it causes the reed switch plates to snap together (if normally open) or pull apart (if normally closed).

1.2 Operating Distance and Hysteresis

A reed sensor typically functions at a relatively short range-1 to 3 cm is common. However:

- Activation Distance (pull-in): The magnet must move within a certain gap to cause contact closure or opening.

- Release Distance (drop-out): The magnet must recede even further for the contacts to revert to their original state.

This gap between pull-in and drop-out distances is known as hysteresis, ensuring the sensor doesn’t rapidly flicker when the magnet is near the activation threshold.

2. Advantages and Limitations

2.1 Key Benefits

- Versatile Environmental Tolerance - Works fine in dusty, wet, or explosive atmospheres since the contacts are sealed.

- No Exposed Sparking - Suitable for hazardous zones.

- Simple, Low Power - Requires minimal current to activate.

- Long Lifespan - Little mechanical wear, given no external friction or arcs.

2.2 Potential Drawbacks

- Limited Load Capacity - Reed switches typically can’t handle large currents or high voltages. An auxiliary relay may be required if switching higher-power circuits.

- Short Switching Distance - Usually no more than a few centimeters, so sensors must be mounted carefully and precisely.

- Magnet Strength Over Time - In some cases, the magnet can weaken with age or extreme temperatures, affecting reliability if there’s not enough margin in the design.

3. Types and Applications of Reed Sensors

3.1 Security Systems

Reed sensors excel as door/window contact switches in home or commercial security. Often called magnetic contact or magnetic reed sensors, they detect:

- Door opening (magnet and sensor separate, causing the circuit to change state)

- Window tampering

- Hatches, skylights, gates

In the USA, you’ll see these widely in home alarm packages-one half mounts on the door, the other on the door frame.

Installation Tip: On metal doors, the steel can disrupt or reduce the magnet’s effective range, requiring a stronger magnet or specialized sensor design. On wood or plastic frames, simpler miniaturized designs generally suffice.

3.2 Liquid Level Detection

Reed sensors commonly appear as part of float switches for water or other fluids:

- A magnet is sealed inside a floating element.

- The reed switch is fixed at a certain level on the tank or vessel.

- As the float rises or falls, the magnet crosses the reed switch’s activation threshold, signaling high or low fluid levels.

This strategy enables multiple discrete levels to be detected by stacking multiple reed switches at different heights-limited only by physical spacing to avoid mutual interference.

3.3 Industrial Position Sensing

For automated gates, conveyor belts, or machine parts, reed sensors can act as end-of-travel switches, confirming whether a mechanical part has fully opened or closed.

- Install the reed switch on a fixed bracket.

- Attach the magnet to the moving part.

- When aligned, the sensor output indicates “position reached.”

3.4 Other Uses

- Limit detection in robotics or 3D printers

- Speed measurement by counting magnet passes on rotating shafts (though short range is a constraint)

- Mailboxes or secure lockers, to log if a container has been accessed

4. Practical Considerations for Wiring

Wiring a reed sensor is straightforward. Most provide two leads connected to the internal reed switch:

- Incorporate them in your control circuit where you need an open or closed signal.

- Determine if your application requires the sensor to trigger on open vs. closed contact (i.e., normally open or normally closed).

- If higher voltage or current is involved, consider using a secondary relay or transistor driver rather than passing heavy loads through the reed sensor.

5. Selecting the Right Reed Sensor

Maximum Current & Voltage

- Check the switch rating (e.g., 100 mA at 30 V DC).

- For controlling larger loads, use an intermediate relay or similar device.

Activation Gap

- If you need a 1-inch (2.54 cm) detection range, ensure the sensor’s design meets or exceeds that.

- Factor in hysteresis-the drop-out distance can be notably larger.

Physical Mounting

- Choose a sensor with a shape and style (surface mount, recessed, miniature) that fits your door frame, float device, or machine part.

Durability

- Look for environmental ratings (like IP67 for moisture).

- In harsh industrial or outdoor US climates (salt, extreme cold/heat), ensure the magnet and reed sensor materials won’t degrade quickly.

6. Key Takeaways

- Reed sensors use a reed switch + magnet to open or close contacts.

- Advantages: No external spark, sealed contacts, compact size, safe in explosive or dusty atmospheres.

- Drawbacks: Limited load handling, short operating range.

- Applications: Door/window security (common in USA residential alarms), float-based liquid level sensing, position detection in automated equipment.

- Installation: Straightforward wiring (two leads), but confirm load specs and mechanical spacing.

For more insights-like recommended reed sensors, US-based suppliers, or tips on maximizing reliability in your specific application-browse safsale.com. Their resources guide homeowners, DIY enthusiasts, and industry professionals in selecting the best reed switches, magnets, and relevant accessories to build dependable automation or security solutions.