Grounding Resistance Measurement: Testing Methods and Guidelines

Why Is Grounding Resistance Testing Important?

Grounding is one of the most critical safety features in electrical systems, preventing electrical shock hazards and protecting equipment from power surges and faults.

A properly installed grounding system:

- Redirects excess electrical current safely into the ground.

- Ensures electrical protection devices (like GFCIs) operate correctly.

- Minimizes the risk of fire and equipment damage.

When and Why Should You Test Grounding Resistance?

Regular testing of grounding resistance ensures the system remains effective and compliant with electrical safety regulations.

- For residential properties, grounding resistance should typically not exceed 4 ohms.

- For commercial and industrial sites, the resistance limit may be stricter.

Preparing for a Grounding Resistance Test

Step 1: Visual Inspection

Before performing any measurements, inspect the grounding system for:

✔ Corrosion on grounding conductors and electrodes.

✔ Loose connections or physical damage.

✔ Proper bonding of all grounding components.

Step 2: Equipment Needed for Testing

To measure grounding resistance, you will need:

- A grounding resistance tester (such as a digital earth resistance meter).

- Test probes and auxiliary electrodes.

- Wires long enough to connect all electrodes in the test circuit.

Methods for Measuring Grounding Resistance

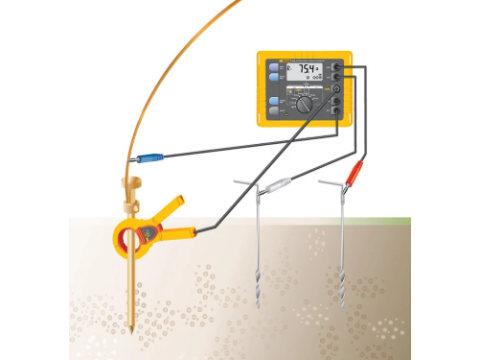

1. The Three-Point (Fall-of-Potential) Method

The most accurate and widely used method for grounding resistance measurement.

How It Works:

- Place two auxiliary electrodes in the ground at a specified distance from the grounding electrode being tested.

- Connect the test leads:

- One lead to the grounding electrode.

- The second lead to the potential electrode (placed at 62% of the total test distance).

- The third lead to the current electrode (farthest from the grounding electrode).

- Run the test – the meter applies a small current and measures the voltage drop, calculating resistance.

Key Considerations:

✅ The electrodes should be in a straight line to avoid interference.

✅ Moisture levels and soil conditions affect readings.

2. Clamp-On Method (Testing Without Disconnecting Grounding)

This method is ideal when you cannot disconnect the grounding system for testing.

How It Works:

- A clamp meter is placed around the grounding conductor.

- The device injects a small signal and measures the current response to determine resistance.

Pros:

✔ No need to disconnect grounding – keeps the electrical system operational.

✔ Quick and easy testing.

Cons:

❌ Less accurate than the three-point method.

❌ Works only on grounding systems with multiple parallel paths.

3. Testing the Grounding System Without Special Equipment

If you don’t have a resistance meter, you can perform a basic check using a voltmeter:

- Measure the voltage between neutral and the grounding conductor.

- The reading should be less than 5V.

- If voltage is higher, the grounding system may be faulty.

Note: This is not a substitute for proper resistance testing!

Factors That Affect Grounding Resistance Measurements

1. Soil Moisture and Composition

✔ Wet soil improves conductivity (lower resistance).

✔ Dry or sandy soil increases resistance.

✔ Frozen ground has higher resistance, so winter tests may show misleading results.

2. Seasonal Changes

Since moisture and temperature fluctuate, grounding resistance should be tested under different conditions to ensure year-round effectiveness.

3. Distance Between Test Electrodes

If the test electrodes are too close together, the measurements may be inaccurate.

- The standard distance for three-point testing varies, but for most home installations, spacings of 50–100 feet are recommended.

Analyzing Results and Documentation

What to Do If Grounding Resistance Is Too High?

If test results show that the grounding resistance is above the recommended limits, corrective actions include:

✔ Adding more grounding electrodes – placing multiple rods in parallel reduces resistance.

✔ Driving existing rods deeper – deeper electrodes reach more stable soil conditions.

✔ Using chemical grounding enhancers – adding special compounds around electrodes improves conductivity.

Grounding Test Report: Required Documentation

All test results should be properly documented in a grounding resistance test report.

What to Include in the Report:

✔ Date and time of testing.

✔ Testing method used (Three-Point, Clamp-On, etc.).

✔ Soil conditions and weather during the test.

✔ Measured resistance values.

✔ Corrective actions (if needed).

Maintaining proper records ensures compliance with electrical codes and simplifies future inspections.

Grounding Resistance Testing: FAQ

1. How Can I Tell If My Home’s Grounding Is Working?

A simple test:

- Measure the voltage between the grounding wire and neutral.

- If it's above 5V, grounding may be faulty.

- For accurate results, use a ground resistance meter.

2. Can I Check Grounding Resistance With a Multimeter?

A multimeter is NOT suitable for precise grounding resistance measurement.

- It can give an approximate resistance reading but lacks the accuracy of specialized equipment.

- A professional earth resistance tester is required for compliance testing.

3. Should Grounding Be Connected to the Neutral Wire?

- In a TN-C-S system, grounding and neutral are only connected at the main electrical panel.

- Connecting them elsewhere is dangerous and against code.

4. How Often Should Grounding Be Tested?

- Visual inspections: Every 3 months.

- Full resistance measurement: Once per year.

- After any electrical system modifications or failures.

5. What Are the Signs of a Bad Grounding System?

If you experience any of the following, check your grounding system immediately:

- Tingling sensation when touching appliances.

- Frequent tripping of GFCIs without clear cause.

- Voltage detected on metal casings of electrical equipment.

- Unusual electrical noise or static interference.

Conclusion: Ensuring Electrical Safety Through Proper Grounding

✅ Grounding resistance testing is essential for home and workplace electrical safety.

✅ Regular testing prevents hazards like electric shock and fire risks.

✅ A properly documented grounding test report ensures compliance with safety standards.

If you suspect issues with your grounding system, don’t ignore them—perform resistance testing and take corrective action to protect your electrical system!