Equipotential Bonding System: Ensuring Electrical Safety in Homes

Why Equipotential Bonding Is Essential

Equipotential bonding is a critical safety measure that prevents electrical potential differences between metallic parts in a home or apartment.

Without proper bonding, unexpected voltage differences can occur, leading to electric shock risks when touching plumbing, appliances, or metal structures.

For example, if you've ever experienced an electric shock from a water faucet, it's likely due to a potential difference between the pipes and another metallic object in your home.

A properly installed equipotential bonding system eliminates these hazards by connecting all conductive components together, ensuring they share the same electrical potential.

Main Equipotential Bonding System (Main Earthing System)

According to electrical safety standards, main equipotential bonding (MEB) is required for all modern homes with a protective earth (PE) conductor or combined PEN conductor in TN grounding systems.

What Elements Must Be Connected?

✔ Protective (PE) or combined neutral-ground (PEN) conductors in TN systems

✔ Grounding conductors in IT and TT grounding systems

✔ External metal pipes entering the home (cold water, hot water, sewage, heating, gas)

✔ Structural steel components of the building

✔ HVAC (climate control) conductive parts

✔ Lightning protection grounding electrodes

✔ Telecommunication cable shields

✔ Secondary grounding electrodes at building entry points

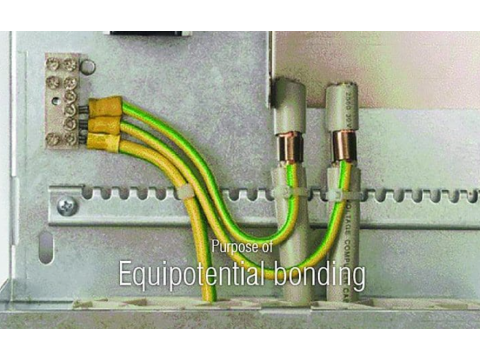

How Is It Connected?

All these conductive parts must be connected to the main grounding busbar (MGB), which ensures a direct and secure link to the home's grounding system.

If a gas pipe has an insulating joint at the building entry, bonding should be done before the joint, as close to the structure as possible.

Mandatory Use of Main Equipotential Bonding

Main equipotential bonding is required when Ground Fault Circuit Interrupters (GFCIs, also called RCDs) or circuit breakers with differential protection are installed.

- GFCIs detect leakage currents that flow through a person, disconnecting power instantly to prevent electrocution.

- If bonding is not installed, a faulty appliance could remain energized even after a ground fault occurs.

Additional Equipotential Bonding System (Supplementary Bonding)

While the main equipotential bonding system ensures electrical safety at the building level, supplementary bonding (SB) provides localized protection inside a home or apartment.

What Does Supplementary Bonding Protect?

✔ Appliances like washing machines, ovens, and water heaters

✔ Exposed metal surfaces near plumbing (sinks, bathtubs, shower frames)

✔ All metal pipes running within a room (e.g., a bathroom)

Why is this necessary?

Even if main equipotential bonding is present, individual appliances may not be properly connected to the main grounding system.

How It Works

- Metallic plumbing and electrical appliances in the same room must be interconnected with a low-resistance conductor.

- This prevents voltage differences, reducing the risk of shock if a person touches both a faulty appliance and a grounded pipe.

Example Scenario:

If a washing machine in a bathroom has a ground fault but is not bonded to metal plumbing, a person touching both could receive a lethal electric shock.

Danger without Supplementary Bonding:

- Electrical faults may go undetected, causing appliance casings to stay energized.

- A person standing barefoot on a wet floor touching a faulty appliance could experience full phase voltage shock.

Solution:

Ensure all accessible metal components in rooms with water (bathrooms, kitchens) are bonded using dedicated grounding terminals in outlets or a separate bonding conductor.

How to Properly Install Equipotential Bonding

Wire Sizing Requirements

To ensure electrical safety, bonding conductors must be sized correctly:

✔ Main Equipotential Bonding

- Copper conductor: ≥ 6 mm²

- Aluminum conductor: ≥ 16 mm²

- Steel conductor: ≥ 50 mm²

✔ Supplementary Bonding

- The conductor size should match the smallest grounding wire of the connected appliances.

To simplify installation, many electricians use a standard 25 mm² copper conductor for main bonding to avoid compliance issues.

Common Mistakes in Equipotential Bonding

Not connecting all metal components

- Leaving pipes unbonded can create potential differences, increasing shock risks.

Using water or gas pipes as ground conductors

- Pipes must be bonded, but should never replace a dedicated ground wire.

Improperly sized bonding conductors

- Thin wires increase resistance, reducing effectiveness.

Failing to include metal bathtubs or showers in bonding

- Water exposure makes these areas especially hazardous if voltage differences exist.

FAQ: Equipotential Bonding in Homes

1. Do I need equipotential bonding in a modern home?

✔ Yes! Even new homes with proper grounding require bonding to prevent electrical shock risks from conductive surfaces.

2. What happens if I don’t install equipotential bonding?

You risk electrical shocks when touching plumbing, appliances, or metal structures.

Faulty appliances may stay energized, causing lethal hazards.

GFCI protection may not work correctly, increasing risk of electrocution.

3. How do I know if my home has equipotential bonding?

✔ Check your electrical panel for a main grounding busbar (MGB) with connections to metal pipes.

✔ Look for grounding terminals in outlets-three-prong outlets should be properly grounded.

✔ If unsure, hire an electrician to test bonding continuity.

4. Do all metal objects in my home need bonding?

Only those that can be touched simultaneously with an electrical appliance.

Examples: Bathtubs, sinks, metal window frames near outlets, metal pipes.

5. Can I use an existing electrical circuit for equipotential bonding?

No! Bonding requires dedicated conductors with proper sizing and direct connections to grounding points.

Conclusion: Why Equipotential Bonding Is a Must-Have for Home Safety

✅ Main equipotential bonding prevents large-scale potential differences across a home’s electrical and plumbing systems.

✅ Supplementary bonding protects against localized electrical faults in kitchens, bathrooms, and laundry areas.

✅ Proper bonding ensures GFCIs work correctly, preventing fatal electric shocks.

✅ Regular inspections and proper wire sizing are essential for long-term safety.

Takeaway: If your home lacks equipotential bonding, have a professional electrician install it to ensure maximum electrical safety!